Higher quality finishing / finishing processes...

Higher quality finishing / finishing processes of surgical instruments / implants Refining or ref...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Higher quality finishing / finishing processes...

Higher quality finishing / finishing processes of surgical instruments / implants Refining or ref...

Finishing processes for medical instruments...

Scissors, handles, drills, clamps, endoscopes and turned and milled parts Medical instruments and...

Laser technology for the medical device industry

ADMEDES customers benefit from the deep process know-how we have earned since our founding in 1996....

Stent production as series applications Thanks to our handling, it is possible to remove stents fro...

40 years of experience in electroplating For four decades, Rudolf Storz has been intensively invo...

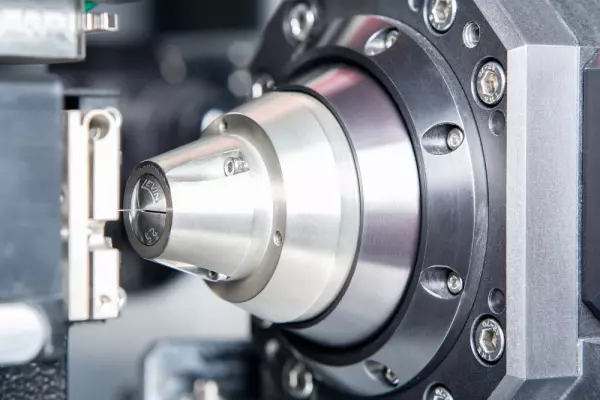

Contract manufacturing of precise turned...

Contract manufacturing of precise turned and milled parts for medical technology perame...

Surface finishing the perfect finish for...

Surface finishing - the perfect finish for your products Manufacturing sophisticated products is...

Your precise partner for metal and plastic...

WEIHBRECHT Lasertechnik GmbH was founded in 1986 with the Swabian inventor's claim “If it...

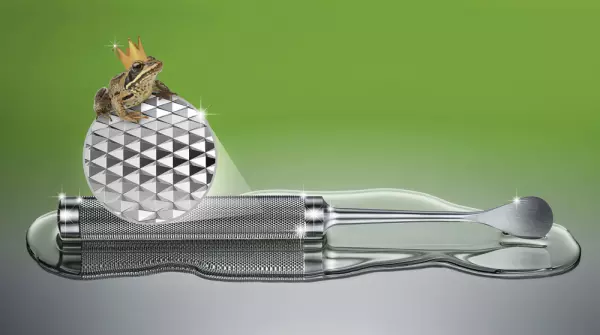

Electropolishing of surgical instruments, electropolishing of medical products, electropolishing of implants

The use of electropolishing for surgical instruments has a number of benefits. These methods are less prone to germ attachment, and provide a smooth surface for a wide variety of medical tools. These methods are particularly valuable in the field of implant surgery, where there is an increasing concern over the use of surgical instruments that are multipurpose. And the results of surgical instrument electropolishing are superior to passivation, which is not a viable option for all devices.

Surgical instruments must be perfectly smooth and free of burrs and edges, as these can compromise accuracy. Additionally, these instruments are often used in medical imaging and diagnostic procedures, which need a smooth conductivity. Imperfections on the surface can create arcs in electrical current, causing distortions and damaging expensive medical equipment. For these reasons, surgical instruments are typically electropolished to improve their performance and life. Here's a look at the benefits of this process.

The electropolishing process removes a microscopically-precise layer of material, resulting in an entirely smooth surface. This makes reusable devices safer for use in surgery. Surgical instruments with an electropolished finish are easier to clean, which helps prevent infections and minor injuries. As a result, surgical instruments are made more durable, and the cost of replacement is lower. They also perform better in diagnostics and medical imaging.

Surgical instrument electropolishing is often done by manufacturers to reduce costs. While it may be less expensive, this method still produces suboptimal finishes and is not recommended for implants. As a result, the quality of medical devices can become inconsistent and patient rejection rates can increase. Besides, electropolished parts will look better and last longer, which is the main benefit for surgeons. Further, the sterilizing features of the process can make these devices more attractive to the consumer.

Surgical instruments with electropolished surfaces are highly resistant to germs. They can withstand bleach, which is an important advantage in bio-pharmaceutical applications. Moreover, they are less prone to bacteria. They can be treated with disinfectants and sterile materials, and the surface will be ready for use in a day. This process is an important step in the process of disinfection. If you don't prefer this process, electropolishing will help you avoid these issues.

Surgical instrument electropolishing is often done to improve the quality of surgical instruments. This process can be done by using a saline solution to create a bright finish or a passivated surface. The process is safe for the environment and workers. It has already been adopted by the BAMA in Milan. There, surgical instruments undergo routine electropolishing to improve their appearance. The procedure is also a good way to eliminate rust.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.