Prototype technologies for medical technology

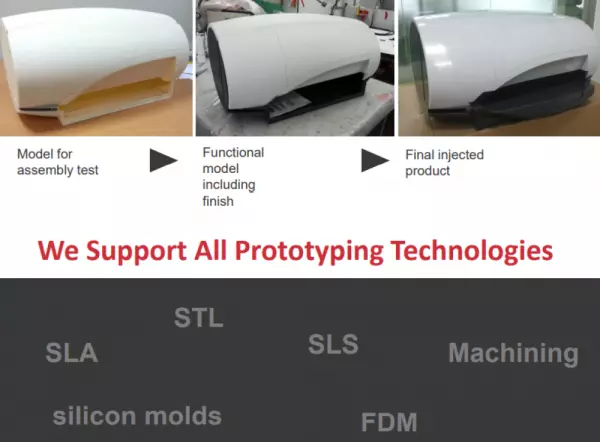

Medical technology Prototyping High quality prototyping is a critical stage in the product developm...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Prototype technologies for medical technology

Medical technology Prototyping High quality prototyping is a critical stage in the product developm...

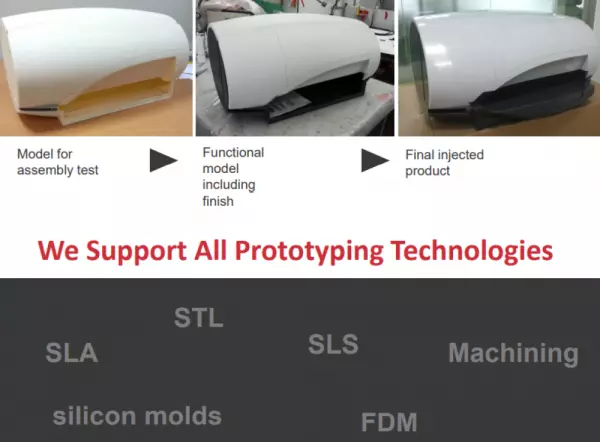

While most consumers are satisfied with the functionality and ease of use of Fused Deposition Modeling 3D printer, these devices can also pose health risks. This is because of the high concentration of airborne particles emitted by FDM printers, a method that is prone to emit billions of airborne particles per minute. Exposure to these ultrafine particles can lead to an increase in oxidative stress, cardiovascular effects, and inflammation. In addition, the inhaled ultrafine particles have been associated with increased levels of styrene, a known carcinogen.

Xometry offers a wide range of rigid plastics for its FDM technology. ASA, an amorphous thermoplastic with improved weather resistance, is one of the most popular materials for FDM printing. ASA also has a broad color range, making it an excellent choice for prototyping. These materials are also among the most common choices for 3D printing, and are commonly used in the medical field.

One of the most compelling benefits of 3-D printing is its ability to create patient-specific surgical approaches. The ability to see anatomical structures with unprecedented clarity is crucial for improving surgical outcomes. The availability of patient-specific models will help minimize the risk of complications caused by inadequate visualization. Standard imaging with MRI, CT, and ultrasound allows for initial visualization of a tumor, but it is impossible to imagine its 3-dimensional structure with such a limited representation. The clinician is forced to mentally recreate complex 3-dimensional anatomy by scrolling through a series of two-dimensional images.

In addition to medical applications, Fused Deposition Modeling has become a mainstream technology for rapid prototyping. Since the FDM process is open-source, enthusiasts have developed their own 3D printers using open-source code. Makerbot, a $400M company, became the largest company based on the open-source movement. It has since gone on to become an industry and is the most popular and widely used 3D printer in the world.

The process of FDM has been around for over a decade and has been widely accepted for direct manufacturing and rapid prototyping. The technology is now being used for the production of biomedical devices during the Novel Coronavirus pandemic. However, FDM printers aren't suitable for all types of manufacturing. They can only be used for certain applications and may not be compatible with all materials.

These devices can be used for medical applications. They can be manufactured in complex geometries and small quantities. The materials used in FDM printers are often expensive to produce, so it is important to consider the cost before investing in this technology. The cost of a 3D printed part is dependent on the final value of the part. When it comes to medical applications, the process of FDM has proved to be a successful alternative for manufacturers.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.