Upper basket for optimal accommodation of...

100 Upper basket for optimal accommodation of injector modules or inserts Upper basket with...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Upper basket for optimal accommodation of...

100 Upper basket for optimal accommodation of injector modules or inserts Upper basket with...

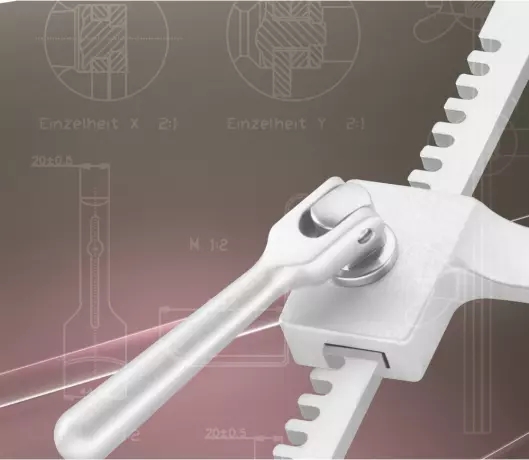

Our speciality: custom-made products You have a new idea or need an instrument solution for speci...

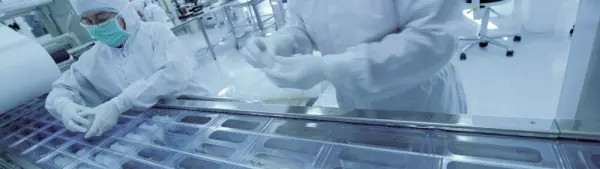

Contract Packaging and Sterilization for...

Contract Packaging and Sterilization of Medical Products From raw material to ready-to-...

Transport trolley for loading and unloading...

MF/3 transport trolley for loading and unloading cleaning and disinfection machines For easy handlin...

Surface finishing the perfect finish for...

Surface finishing - the perfect finish for your products Manufacturing sophisticated products is...

Post-processing of ready-to-install parts

We supply you with ready-to-install parts More and more manufacturing companies are reducing their v...

Electroplating and P VD services

There are many good reasons to choose PVD technology: in addition to the low chemical loa...

Healthcare & Medical assemblies

We are the reliable partner covering all areas from conception to (sterile) packaging of the finishe...

Cleaning, packaging and storage solutions...

Our offer to you! We offer cleaning, packaging and storage solutions for components from the medi...

The proper point of use care of surgical instruments and equipment is critical to avoiding infections, and is essential for ensuring sterility. Since surgical instruments are complex and come in many shapes and sizes, they can be tricky to disinfect and reprocess, making them an expensive risk to the health system. The correct methods for sterilization should be followed both in the operating room (OR) and the post-operative decontamination (SPD) area.

In the operating room, the proper cleaning and disinfection of surgical instruments must begin as soon as possible. Once a surgical instrument has become contaminated, it should be washed in sterile water, and then sprayed with enzymatic instrument foam. This foam helps keep the instruments moist while the process starts. Once this is completed, the instrument is ready to use. After removing it from the water, it should be dried thoroughly with a towel.

Surgical instrument washing and cleaning begins before surgery in the operating room. After the procedure, the instruments should be placed in sterile water with an approved enzymatic detergent. It is also recommended to spray the surgical instruments with an enzymatic instrument foam, which will prevent the blood from drying out. Once the instruments have been cleaned, they should be rinsed and dried thoroughly. The surgical staff should be thoroughly trained on proper instrument washing and disinfection practices.

Surgical instruments need to be properly washed and disinfected. Infection-prone instruments need special attention, which is why it is vital to ensure proper cleanliness. A clean instrument means a healthy patient. It can improve surgical results, and prevent infections. Using a proper cleaning solution helps prevent infection-causing microorganisms from re-growing on the instrument. Soapy sanitizer is not recommended.

Surgical instruments are the most expensive reusable medical devices. They are crucial to a surgeon's workflow and can also help prevent infections. They should be cleaned and sterilized at the point of use, which is a very important step in instrument care. The procedure should begin within 10 minutes of surgery, and the surgical instruments should be kept wet until the procedure is completed. To pre-clean an instrument, a neutral pH soap should be used. Chlorhexidine and Betadine can cause corrosion and spotting on the instrument. It should be rinsed thoroughly.

A sterilization solution should be used for surgical instruments and equipment. It should be able to kill bacteria and other pathogens. It should be sterile and free from contaminants. While a washer-disinfector is a great choice for sterilization, the bacterium-free devices are only suitable for hospitals and other health facilities. If you are considering this process, check the manufacturers' documentation for specific requirements.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.