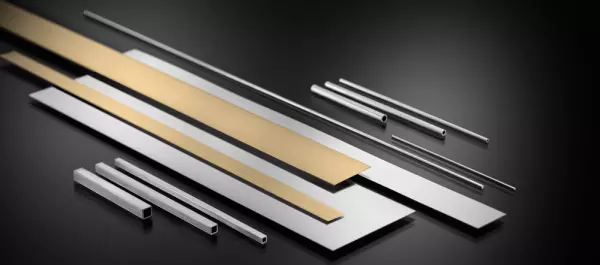

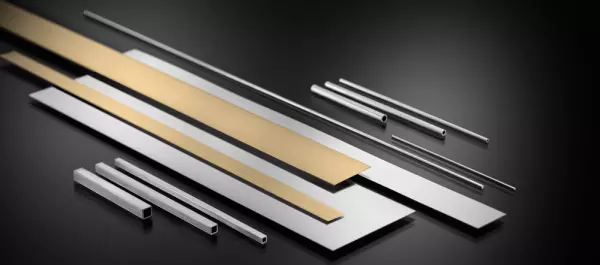

Precious metal semi-finished products

No matter what challenge you’re facing, we have the right precious metal semifinishe...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Precious metal semi-finished products

No matter what challenge you’re facing, we have the right precious metal semifinishe...

Orthopedic Products - Inserting Tools

The product range of cutting tools in the field of orthopedics includes: Phillips blades...

Orthopedic products - Navigating tools

Customized tools for navigating the drill holes and saw cuts

Customers appreciate our versatility and precision. On high-quality machining centers, 3-axis and 5-...

Raw materials for various surgical instruments

Since the company was founded in 1880, we have been manufacturing raw materials for various surgical...

Instrument blanks are made from raw steel. The process involves milling away excess metal from a piece or die-forging the whole instrument. The finished piece is then heat-treated and tested for hardness, ratchet action, and other properties. There are many types of blanks available. A few of the most common include tiger larch, crotch maple, and ebony. There are also several different types of exotic woods that are used to make instruments.

A blank instrument is an instrument that lacks the analyte of interest. It is used to monitor sample degradation and trace the origin of contamination. In addition to determining the true course, blanks also allow the user to track the artificially introduced contamination. It's important to understand what a blank instrument is used for before constructing one. Some manufacturers provide blanks for the purpose of screening the dimensions of instrumentation. You can also use blanks to check the function of an analyte.

While the FDA regulates the quality of medical devices, counterfeit products have entered the US market without FDA clearance. They may also lack adequate instructions for processing and use. To prevent these issues, it's advisable to buy blanks only from a reputable instrument manufacturer. Unfortunately, counterfeit products have made their way into hospitals and other settings. While they're generally expensive, you can find them for less than $50. As a rule of thumb, don't go with low-cost instruments.

In some instances, the instruments on an instrument blank panel differ in quality. A manufacturer's explanation will explain the differences between different types of stainless steel and ebonite. The manufacturer will explain their differences and explain why the differences exist. You can use these blanks to simulate the different instruments and equipment. This will make it easier to find the right ones for your purposes. You can even experiment with these blanks and see which ones are best suited for the purpose.

Using an instrument blank can help you get an accurate reading of the measurements. An instrument blank is made from the same substance as the sample. This blank allows you to smoke out what the aircraft has and to determine the noise of the instrument. This is an important part of quality control, but it can be hard to see with the naked eye. It's the main tool that a researcher will use to measure the differences in the different elements of the sample.

An instrument blank panel can be made from a thin sheet of plastic. It is also made to be trimmed according to the aircraft's specifications. If it is a temporary panel, you can mount it flush to ensure a smooth and secure fit. If it's permanent, it can be permanently attached to the panel. But if it's temporary, it's a good option for a temporary panel. In addition to their strength, they are also easy to install and require no special skills.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.