Out of a special fascination for technical cleanliness, Dipl. Ing. Volker Burger founded the company CleanControlling on April 1st, 2006. Since then, CleanControlling has made a name for itself as a leading international specialist.

During his work as head of process and product development at an automotive supplier, Volker Burger was repeatedly confronted with the challenges of the then still "young" topic of technical cleanliness. With this extensive experience from process and product development in connection with technical cleanliness, Volker Burger continued to develop not only analytics, but also consulting services and the range of training courses on this topic. CleanControlling advises and supports well-known OEMs and automotive suppliers, but also manufacturers from other industries, for whom technical cleanliness is becoming increasingly relevant, in the planning and design of clean production and assembly processes.

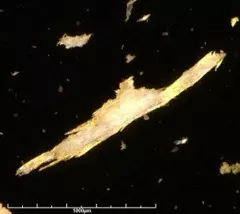

With its early entry into the world of technical cleanliness, CleanControlling has been intensively involved in committees and standards committees for the practical interpretation of guidelines and standards over the past 15 years and has given important impulses for the further development of these regulations. In addition, the variety of methods for the extraction and analysis of particulate impurities has been refined and established. The experiences from the consulting projects and from the analysis already flowed into the development of a specialized product range in 2015, which is now presented in an extensive product catalog and eShop. The international distribution of the product range is an essential part of this business area.

With Volker Burger's vision of building and positioning CleanControlling as the specialist for all aspects of the surface cleanliness of technical components and medical products , further chemical, biological and microbiological test methods were established beyond the range of relevant variants of particle analyzes. The increasing requirements in the area of chemical-filmic component cleanliness have led to the establishment of further processes in chemical analysis. Furthermore, with the proximity to the medical device manufacturers in the "world center of medical technology" in connection with the focus on surface cleanliness, the essential factors are given to support the medical technology industry with a wide range of tests to ensure the safety of medical devices with regard to the application in or on people.

With over 90 employees, CleanControlling is now one of the most important contacts for technical cleanliness and surface cleanliness in automotive and medical technology.

Milestones in the company's development

- Active participation in the industrial network TecSa 2.0 - VDA 19.1

- Active participation in the AdhäSa industrial association

- Participation in the standards committee for the revision of ISO 16232: 2018

- Establishment of the air extraction through flow with a special through flow test bench

- Specialization in the development, design and manufacture of component-specific test adaptations

- Establishment of the CCPlus cleanliness test for increased blank value requirements

- Development of suction extraction as a practical extraction method in the field of e-mobility

- 2014: Company foundation of CleanControlling Medical GmbH & Co. KG

- 2015: move into and inauguration of the new company building

- 2016: Product development of particle suction extraction system, manual and robot-assisted

- 2019: Establishment of analysis methods to determine the chemical-filmic component cleanliness

- 2020: Establishment of the Dresden branch

To the original article