Keeping the automation of tomorrow under control

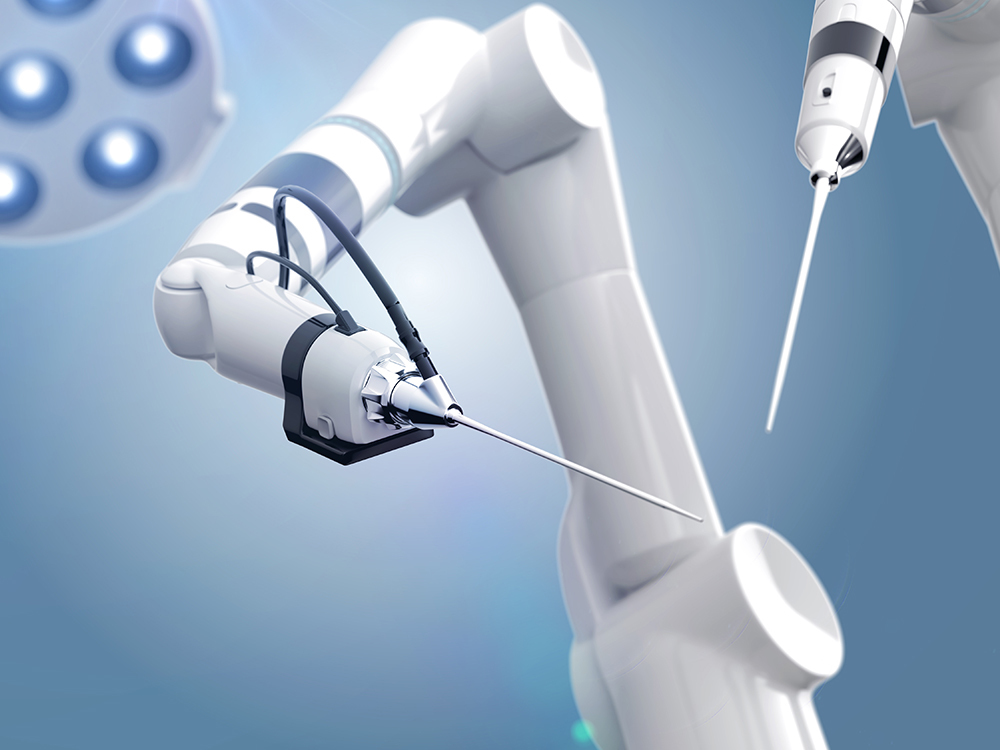

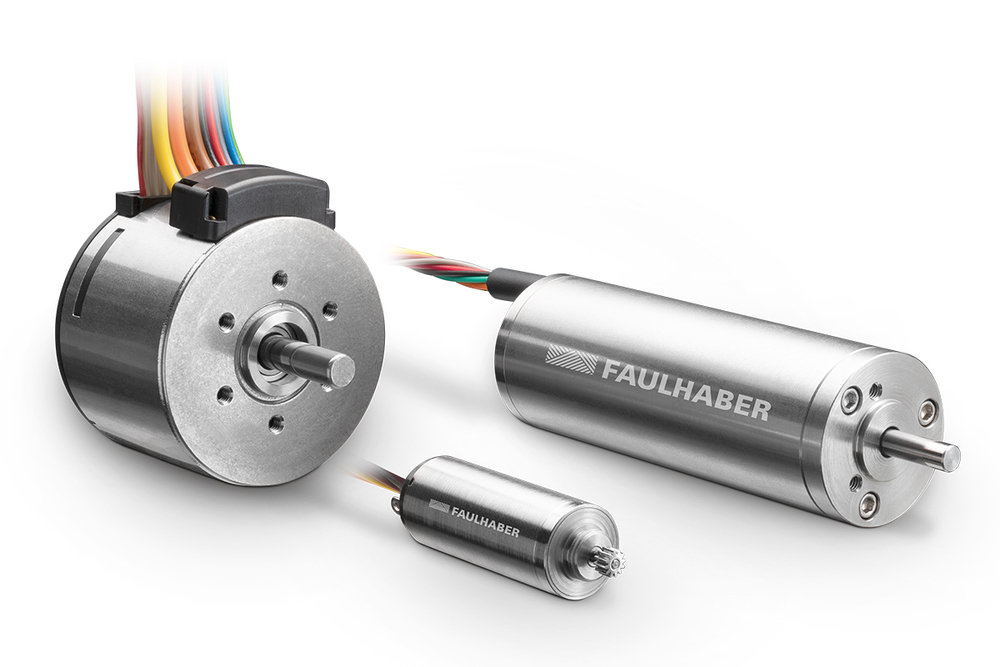

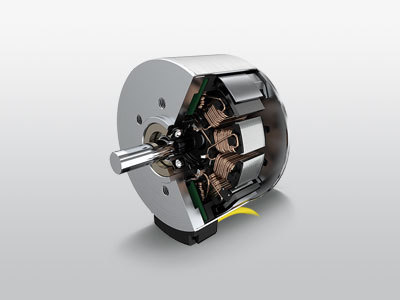

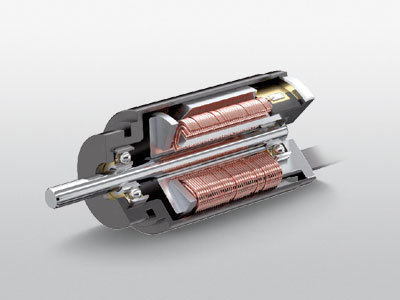

A world without robots is unthinkable today. The areas of application that demand process security, reliability and cost-effectiveness from these are correspondingly diverse. The drive systems from FAULHABER make a significant contribution to meeting these requirements and are always convincing thanks to their endurance and performance with a robust, compact design. Their range of applications is therefore broad and ranges from sewer robots and remote-controlled manipulators to robots for handling and logistics to OR applications or prostheses. Regardless of whether high dynamics or precise positioning are required, in the extensive product portfolio with more than 25 million possible combinations of small drives, optical, magnetic or absolute encoders as well as speed and motion controllers with a wide variety of interfaces, there is practically always a suitable solution. At the same time, this "modular technology system" forms the basis for realizing application-specific special requests if necessary and for further advancing robotics.

For example, small grippers that are both fast and powerful were only possible pneumatically in the past. Because with compressed air, a lot of power can be transmitted with practically no time delay. The complex infrastructure required for this is no longer necessary. Today, thanks to brushless DC motors with a diameter of only 22 mm and an integrated motion controller, mechatronic gripping systems easily achieve the performance of their pneumatic counterparts.

Small drives are also on the move in the sewer system. DC motors with a diameter of just 15 mm and a precious metal commutation system show inspection robots in daily use how overload-capable, robust and shock-resistant they are. The small drives also demonstrate these properties in logistics. Intelligent robots are taking on more and more work steps here, both during storage and removal and preparation for dispatch. A typical structure consisting of a lifting column and gripper on a logistics robot contains, for example, brushless DC servomotors with an integrated motion controller and planetary gear as a drive unit. When used in the lifting column, this combination ensures precise positioning when storing or retrieving and that in continuous operation with constant load changes. There is hardly an area in robotics in which the small FAULHABER drive systems are not represented.