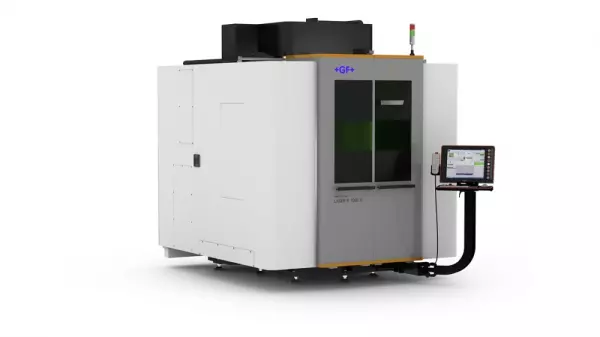

Lasertreatment surfaces LASER P 400 U

The Laser P 400 U Series from GF allow the creation of various surface properties in combination wit...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Lasertreatment surfaces LASER P 400 U

The Laser P 400 U Series from GF allow the creation of various surface properties in combination wit...

Laser texturing is a method of preparing surfaces for adhesive bonding. This technique produces a robust and predictable bond. It is free from stress, microcracks, and surface defects, and does not cause any chemical changes or stress. This process enhances mechanical interlocking of bonded parts and improves their strength, wettability, and porosity. A laser texturing procedure is highly specialized, requiring a high level of expertise.

Different applications require different wavelengths, so different types are needed for different materials. In this case, single laser systems are the most suitable, as they offer greater control over the laser texturing process. A mode-locked laser is an excellent choice for medical applications, as it can be used to perform non-thermal ablation. Besides, single spatial mode beam profiles are required for all kinds of texturing. The size of the focused spot determines the fine texture.

The main disadvantage of laser texturing is that it is limited by the lens of the laser. This means that it is not possible to create intricate patterns. In addition, the machine has to readjust constantly in order to finish a part. However, automatic positioning of the lasers could overcome this barrier and make the process much faster and more precise. The ability to adjust the Laser's focal point would allow for more complex patterns. Hence, automatic adjustment is a significant advantage in the production process.

In addition to this, laser texturing can also be used to protect against counterfeiting of medical parts. This technology has been applied to various medical parts. The nano-scaled texture code created by the software would be unique and could prevent the counterfeiting of medical components. Eventually, this technology could help with the traceability of medical parts. When properly applied, nano-scale texture codes can improve the accuracy and predictability of a component.

Surface texture is an important aspect of product design. It can make an item more ergonomic and improve its grip on surfaces. Its application in medical devices can make a surgical tool pick up less debris and fluid, and can even be used to add textures to aid implant acceptance. Aside from being an aesthetic advantage, laser texturing is a greener technology. Its environmental benefits make it the best way to ensure safety and quality. Its advantages can also help protect against counterfeiting.

In the medical industry, laser texturing is an increasingly popular method of plastic injection molding. In addition to creating new shapes for medical devices, laser texturing can also be used to create intricate designs and intricate patterns. Furthermore, it can produce sharp edges and textured surfaces, and can enhance the appearance of medical products. This technology has many applications, and the benefits are endless. If you want to learn more about laser texturing, you can download the free copy of this article.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.