Linear motors from FAULHABER – Exceptionally...

When it comes to executing translational motions as efficiently and flexibly as possible, linear mot...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Linear motors from FAULHABER – Exceptionally...

When it comes to executing translational motions as efficiently and flexibly as possible, linear mot...

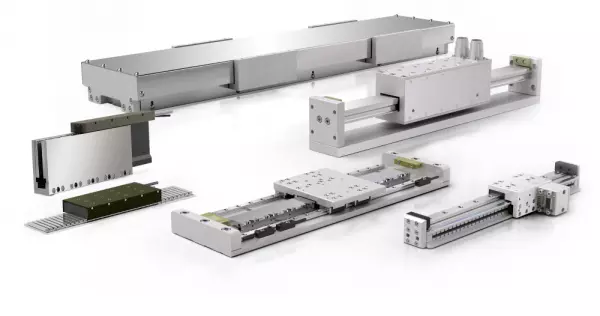

Linear motors / linear axes The CPC portfolio also includes numerous linear motors and linear axe...

Coreless DC motors from FAULHABER – without...

Coreless DC motors from FAULHABER differ from conventional DC motors with iron armatures primarily d...

Linear motors for medical technology, linear drives for medical technology, linear drive technology for medical technology, linear motors for medical technology, linear motors for laboratory technology, linear motors for analysis devices, linear motors for dental technology, linear motors for medical products, linear motors for laboratory devices, linear motors for dental devices, linear motors for medical devices

Linear motors can be described as AC induction motors unwrapped. Their rotor consists of a moving platform and their stator consists of coil windings. When current is turned on, the secondary moves past the primary, which propels it to turn. The rotor is fixed in place. A magnetic field translates the rotary motion into linear motion. The rotor is moved past the stator and is thus able to rotate.

A linear motor consists of electromagnetic windings that float on an air gap between them. The mechanism of electromagnetic levitation is described in US Patent#4,040,983 and is patented by the US Patent and Trademark Office. As the market continues to grow, linear motor technology will be the next step in the evolution of electrical motors. It will also make it easier to integrate controls and provide higher levels of performance in a small package.

In the medical industry, linear motors are used in surgical instruments. They offer high-speed travel while being very small. This makes them perfect for use in medical devices. Aside from the medical field, their small size and low cost make them popular for many applications. There are many benefits of using linear motors in surgery. The technology is flexible and can be used for complex procedures. The benefits of these devices are numerous. The best advantage of using them is that they are cost-effective and space-saving.

A mechanical transmission component is also beneficial in a motion system. It provides a damping mechanism that can attenuate oscillations and disturbances. These components are not required for linear motors to provide the desired settling time and positioning accuracy. They can be very complex and require a controller. The resulting mechanical transmission system can be expensive and requires a large amount of power. However, the benefits of using a hybrid stepper motor are worth the extra expense.

A linear motor is an electric motor that produces motion in a straight line. Traditional electric machines have a rotor inside a stator, while a linear motor's "rotor" moves past the stator in a straight line. They are usually designed to be energy-efficient. HIWIN miniature linear guideways are ideal for small-scale applications. They are highly accurate and have low maintenance. In contrast to MRIs, a typical CT scan requires three hours of work to complete.

A linear motor is constructed much like a brushless rotary motor, except that it's flat. In addition, a linear motor is a direct-drive system, and the forces it produces are limited only by the magnetic forces and the number of coils. As a result, linear motors are often used in automation applications. It's also widely used in industrial 3D printers. If you're looking for an electric rotary-motor alternative, check out the Ball Screw.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.