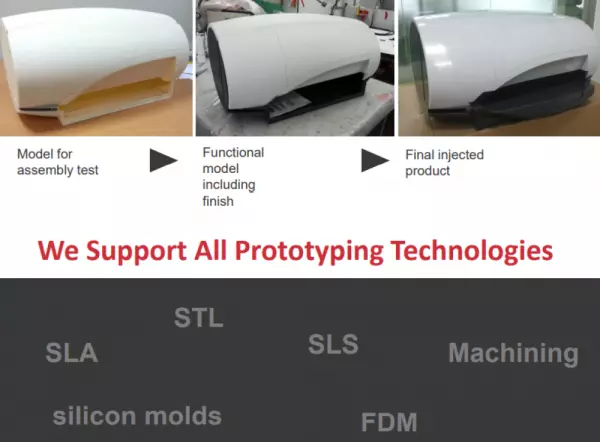

Prototype technologies for medical technology

Medical technology Prototyping High quality prototyping is a critical stage in the product developm...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Prototype technologies for medical technology

Medical technology Prototyping High quality prototyping is a critical stage in the product developm...

The most common feature of a stereolithography 3D printer is the resin tray. Some models also include a mobile platform and scraping system. The stereolithography process uses a UV laser, focusing optics, and mirror galvanometrics to build the part. This process produces durable parts with tight tolerances. This method is popular for the creation of molds for plastic injection and other industrial applications.

This process is extremely versatile and is capable of producing virtually any synthetic design. However, it can be expensive. Due to public interest in 3D printing, the industry has developed consumer-grade SLA machines for under $1,000. In addition to the SLA and DLP methods, LCD panels are becoming increasingly popular for creating synthetic objects. The LCD displays allow you to see the entire object while UV LEDs expose the entire layer. The LCD panels can produce objects with resolutions as high as.001mm.

This technology is a game changer for manufacturing. These machines allow manufacturers to produce entirely new products from scratch. In the medical field, doctors are designing new tools to make difficult surgeries easier and improve patient outcomes. Some examples of this innovation include antibacterial tweezers and prototypes of keyhole surgery tools. These printers are helping doctors create more effective medical instruments. For example, the Pathfinder ACL Guide is made of biocompatible metal and can be produced at 97% of the cost of a traditional cast.

The main disadvantages of stereolithography 3D printing include the cost and complexity of the resins used in the process. This is a drawback of many stereolithography systems. The cost of the resins and the process of printing the parts is relatively high, as the waste is essentially the support structure and residual material. The results are not immediately usable and require extensive post-processing. You'll need to wait for the finished part to be fully processed before you can use it.

Unlike traditional 3D printers, stereolithography 3D printers are very easy to use. Most of these machines have only a few moving parts and are very compact. Despite the simplicity of the process, these printers are a complex machine to operate. So, if you're a beginner, you can easily get started by reading 3D printing reviews. They will help you choose the right machine for your needs.

The technology has many advantages. The resins used in stereolithography 3D printers are made of a polymer. They are made of a variety of materials and are compatible with different materials. The xMED412 is a polypropylene-like material that is biocompatible and can be used to manufacture medical devices. It is covered by a Loctite MED412 material.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.