Direct drive with very large aperture and...

With its DM66200H series, FAULHABER is opening up a whole new dimension in performance for motors wi...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Direct drive with very large aperture and...

With its DM66200H series, FAULHABER is opening up a whole new dimension in performance for motors wi...

Planetary gearboxes – robust and precise

Thanks to their robust construction, FAULHABER metal planetary gearboxes in combination with FAULHAB...

During the 1980s, the founders of PiezoMotor AB, Professor Stefan Johansson and Dr Mats Bexell start...

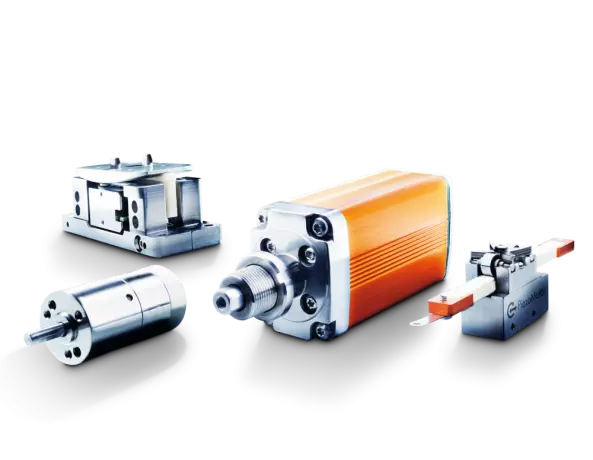

Most users do not need individual motors to realise their drive solutions. They are better off with...

Linear motors from FAULHABER – Exceptionally...

When it comes to executing translational motions as efficiently and flexibly as possible, linear mot...

Motors with integrated Electronics

FAULHABER Motion Control Systems combine the high performance of a FAULHABER brushless motor with ta...

Drives for point of care (PoC) analysis devices, drives for medical technology, drives for laboratory technology, drives for dental technology, drives for medical products, drives for laboratory equipment, drives for dental equipment, drives for medical equipment

Drives are devices used to operate moving objects. They control the speed, direction, and torque of the motion. Electrical drive types are a common choice in applications where the speeds of a load need to vary. Variable speed drives are more effective for these purposes because they can operate the load at varying speeds, and their low price makes them a viable option for many industries. However, these units must be maintained properly, which can lead to costly downtime and delays.

When it comes to connectivity, AC drives come with dedicated software to make maintenance simple. These software applications feature setup wizards, graphical signal monitoring, and parameter editing. Most manufacturers program default values for most AC drive parameters. To customize your drive's operation, you must load values of motor data. You can also use preprogrammed macros to save specific parameters for a variety of applications. These tools will help you optimize your AC drive's performance.

AC drives are designed with plug-in field bus control options. This allows them to connect to major automated systems like PLCs, PCs, PACs, and SCADA systems. They are also compatible with a variety of communication field bus systems, including DeviceNet, PROFIBUS DP, ControlNet, Ethernet/IP, and more. This means that AC drives can connect to a variety of external devices, as well as with other computers connected to the network.

Modern AC drives provide more flexibility than ever. Because they're not hardwired, AC drives are easy to reconfigure for new applications. They also feature analog and digital inputs, relay outputs, and I/O status software for monitoring inputs and outputs. And unlike conventional hard disk drives, modern AC drives feature removable programming panels. If you're not sure what features you need, consult with a professional. If you're looking for storage capacity for your camera, an AC drive will be the perfect choice.

The most basic AC drive consists of disk platters made of glass, ceramic, or aluminum. The disk platters are placed around a spindle inside a sealed chamber and rotate at a high rate of 15,000 rotations per minute. A second motor in the same compartment controls the movement of the read and write heads. They have a large number of advantages and disadvantages, but a lot of people find them too expensive.

When a computer crashes, it can be a real nightmare. An AC drive is an AC drive without any moving parts, and will continue to work for days. The power isn't lost, and you can continue operating your computer. You can also use it to restore a damaged machine. There are no limits to how much you can save with an AC drive. You can also replace it with a new one. But it's not a good idea to buy a cheap, outdated AC drive.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.