Saws / laser welding machine / other

1 x hydropneumatic aluminum circular saw machine Eisele Cutting area 100x100 mm or 160x80 mm, repea...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Saws / laser welding machine / other

1 x hydropneumatic aluminum circular saw machine Eisele Cutting area 100x100 mm or 160x80 mm, repea...

Laser technology for the medical device industry

ADMEDES customers benefit from the deep process know-how we have earned since our founding in 1996....

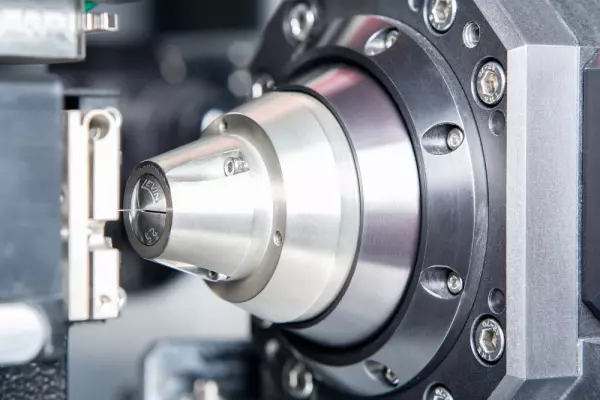

The benefits of laser welding are vast. They are highly accurate, allow for extremely narrow weld points, and have high weld rates. Because the energy used is concentrated, the resulting welds have a better quality than those made with conventional welding methods. Many manufacturers of these laser welding machines are Orotig, which is the world's largest manufacturer of laser welding machines that use pulsed light. The process works well on most types of metals, but is especially effective on stainless steel and carbon steel. The use of filler materials makes this technology ideal for the fabrication of parts for the aerospace industry.

The most important feature of a laser welding machine is its ability to work on various metal materials. It can weld a variety of materials, including stainless steel, titanium, and more. The most advanced laser welding machines are able to weld metal up to 8 mm thick and can even be used on the smallest pieces. The most commonly used material is stainless steel. In addition to stainless steel, laser welding machines are also ideal for aluminum, copper, and copper.

The next generation of laser welding machines incorporate factory automation and integration capabilities. This machine features a large viewing area with slotted access holes to allow long endoscopes to be safely welded. The maximum welding power is 150 W, which can complete a single pulse weld on steel parts up to 1.5 mm thick. The focused spot diameter can vary from 0.2 to two millimeters. MicroWeld(tm) allows 0.1 mm precision welds.

Unlike conventional welding processes, lasers are ideal for fine metal components. Because lasers have very narrow beams, they can effectively weld dissimilar materials. This is particularly advantageous for miniature components, because the amount of scrap produced is minimal. It also generates low internal stresses, and is very clean and hygiene-friendly, making it ideal for assembly lines. Further, a laser is also a versatile tool in the production of medical devices.

A laser is a very precise tool that can weld metals. Because lasers are so precise, it is the only way to create a high-quality joint. In addition to welding metals, lasers can be used to repair medical devices and other types of plastics. There are numerous advantages to using a laser welder. These machines are a great way to get the job done. You will be glad you did!

In addition to laser welding, laser cutting is an efficient method of assembling medical devices. Its low heat output produces few weld debris, so it is ideal for manufacturing devices. As a result, the equipment can also be customized for specific applications. Some of its uses include the manufacturing of disposable stone baskets, balloon catheters, and zebra guide wires. It is also effective for a wide range of other products.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.