Intelligent component alignment for medical...

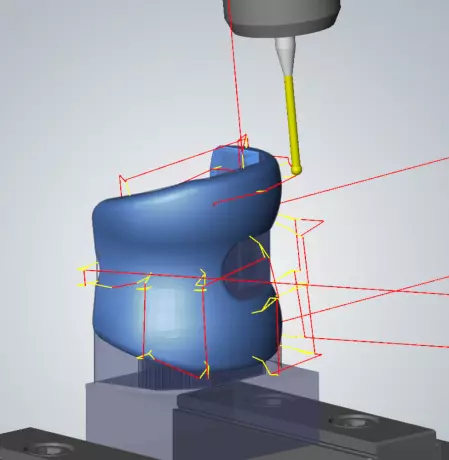

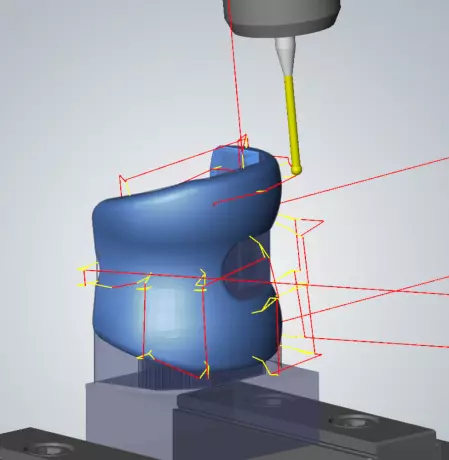

Intelligent component alignment at the push of a button Do you know the problem? You align the r...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Intelligent component alignment for medical...

Intelligent component alignment at the push of a button Do you know the problem? You align the r...

Saws / laser welding machine / other

1 x hydropneumatic aluminum circular saw machine Eisele Cutting area 100x100 mm or 160x80 mm, repea...

Thanks to the technical equipment and the modern machine park at Brecht, you are optimally prepared...

Turned parts for medical technology and mechanical...

Swiss turning Turned parts for medical technology and mechanical engineering Long turning with 2 to...

A lathe is a machine used for turning and milling materials. A rudimentary lathe consists of a wheel that rotates the workpiece while keeping it stationary. A workpiece is turned by moving the head and cutting bits across a bed. These parts move in and out of the bed, causing the workpiece to rotate. A more complex lathe can be used to produce precision parts for car engines, medical devices, and aerospace components.

The most common type of lathe is the Swiss-style lathe, which offers repeatability and precision. These machines use guide-bushing design to provide support close to the cut. While Swiss-style lathes are commonly used in the aerospace and military sectors, the US medical market is an even better place to find them. Their ability to handle tough materials and intricate components allows them to be used in many applications. These machines are ideal for a wide range of applications.

A metalworking lathe is a machine used for metalworking. The carriage consists of an apron and saddle. At the top, a cross-slide sits across the bed. It can be cranked at right angles to the bed. The cross-slide is connected to a toolpost. The toolpost holds the cutting tool and a leadscrew moves the cross-slide.

A lathe is a large machine that is used for machining and cutting. A lathe is a simple and effective way to remove material. The tool is held securely in the headstock or tailstock, while the workpiece rotates. Unlike a conventional saw, a lathe is a highly complex machine that is not easily maneuvered. Aheadstock is where the workpiece is positioned while the tailstock holds the workpiece while the lathe rotates, while the tailstock holds the workpiece. The latter is used for exceptionally large and complicated workpieces.

A lathe works by rotating a workpiece to a cutting tool. The workpiece is held securely and rotates while the tool presses into it. This process allows the removal of material without damaging the piece. A lathe is a very large, complex machine, which has many different parts and can be operated by two operators. The headstock, which holds the workpiece as it rotates, is used for large and complex workpieces, while the tailstock is used for small and medium-sized pieces.

The headstock of a lathe is the main part of a lathe. It holds all the parts together, and is a very useful part of a machine. Its tailstock can be mounted directly to the headstock spindle, so it can be easily accessed. If you're looking for a powerful machine for the medical industry, you'll need a CMZ cnc lathe.

All lathes have a way of changing the speed. For larger diameter turnings, you'll need slower speeds. A few lathes use a belt with stepped pulleys and need to be turned off before you can change the speed. Most lathes, however, have variable-speed motors and allow you to adjust the speed as needed. When choosing a lathe, make sure to check the manual to see if it has an adjustment that allows you to do so.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.