Thanks to the technical equipment and the modern machine park at Brecht, you are optimally prepared...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Thanks to the technical equipment and the modern machine park at Brecht, you are optimally prepared...

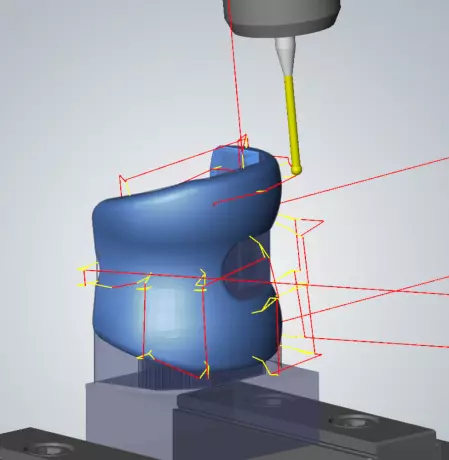

Milling Mikron MILL P 500 / MILL S 400 U

High Efficiency, High Performance, High Speed Cutting 3 milling technologies - one supplier. P...

Saws / laser welding machine / other

1 x hydropneumatic aluminum circular saw machine Eisele Cutting area 100x100 mm or 160x80 mm, repea...

Intelligent component alignment for medical...

Intelligent component alignment at the push of a button Do you know the problem? You align the r...

A milling machine is one of the most common machine tools used in modern manufacturing. From large assembly lines to high-end scientific laboratories, you can find them everywhere. Even in small tool and die shops, you can find a milling machine. Their versatility is unparalleled. From simple round shapes to complex 3-D shapes, milling machines can be used to produce anything from jewelry to airplane parts. Read on to learn more about the different types of milling machines and how to choose the right one for your needs.

A milling machine can be a vertical or horizontal spindle machine. It may also be a two-axis milling machine. Both types have their pros and cons. The horizontal spindle milling machine is more versatile, while the vertical version is easier to use. Both types of machines have two motors and one drive. Both types are versatile, but both place work in the same spot. Some machines have spare parts that can be lifted off when not in use, while others have retractable parts that you can store when not in use.

DWX milling machines are designed for precision and versatility. These machines are perfect for dental and medical applications. You can manufacture custom dental bridges, dental crowns, and medical implants with the MDX series. These machines are built to meet FDA standards. The high-quality milling results made by these machines will be highly visible and durable. These milling machines are also available for medical marking. You can find a milling machine that suits your needs by visiting the Roland website.

A milling machine has many applications, and a good knowledge of the basics is important before you use one. The first one you use will depend on your project and skills. You will have to experiment with the machine to find the best option for you. You can try it out on paper or in a model to see if it will work. Once you know how it works, you'll be better able to determine which type will suit your needs.

A milling machine can be vertical or horizontal. Its blades can be either horizontal or vertical. They are usually used for cutting gears or threads. They can be used for many types of work. If you need a piece to be made of metal, a milling machine will cut it accurately. A milling machine will also be able to cut wood. Some milling machines can also be converted to make metal. The advantages of this milling machine are many.

A milling machine is often used for manufacturing medical components. This process is more cost-effective than injection molding. The tool that you use can be reused many times. Its ability to reuse old pieces helps you to cut down on production costs. In addition to helping you make the best product, a milling machine can also help you save money. You can find a milling machine to fit your needs. All it takes is a few steps to ensure the quality of your work.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.