Electroplating and P VD services

There are many good reasons to choose PVD technology: in addition to the low chemical loa...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Electroplating and P VD services

There are many good reasons to choose PVD technology: in addition to the low chemical loa...

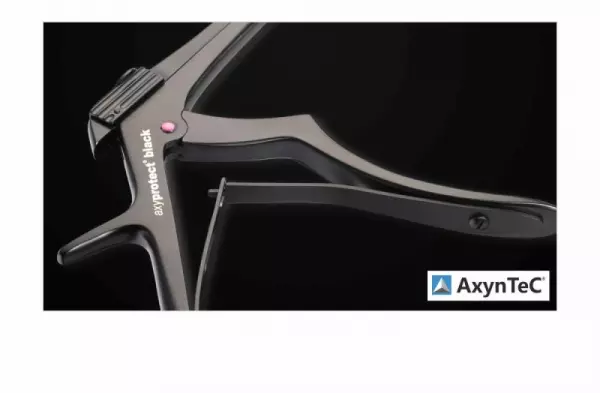

axyprotect BLACK | DLC coating

Diamond-like carbon layers (Diamond Like Carbon, DLC, aC: H or aC: H: X) are a class of ma...

PVC coating of medical components, PVC coating of medical components, PVC coating of medical materials, PVC coating of medical products, PVC coating of medical devices, PVC coating of surgical instruments

Despite its durability, PVC coatings are prone to damage. Accidents or hard surfaces can cause damage, and tools may fall into the conduit. A PVC coating's manufacturer should be able to help you determine if PVC is a good option for your process. If it isn't, you can discuss other options. Read on to learn more about the advantages and disadvantages of PVC coatings. After all, they've been in the business for decades!

The benefits of PVC coatings include durability and flexibility. The plastic can be available in a variety of colors and thicknesses, and is chemically stable and resistant to high temperatures. Vinyl coated polyester is a common material for flexible fabric structures, and it can be chemically and waterproof. A PVC coating will also improve the strength of your fabric. It can be tailored to meet your exact needs, too. And, you can even customize the thickness of the coating.

A PVC coating is great for a variety of applications, including electronics and home appliances. It is water and chemical resistant. It is widely used in wires and chords, frozen food shelving, dishwasher baskets, chain link fences, and other products. It also provides insulation and is FDA-approved for food processing. You can even customize the thickness and texture of the coating to match the surface of your product. There are many types of PVC coating available.

PVC coatings are often decorative or protective. Depending on the application, they can be made of any material, from steel to wood. The main benefit of PVC coatings is that they can be applied to nearly any surface. In fact, dip coating can coat just about any large object. This makes it the third most popular plastic coating in the world. If you're looking for a replacement for plastisol, consider using PVC.

A PVC coating is a great choice for exteriors. It can be decorative or protective, but the best part is that it doesn't have to be ugly. It's the third most commonly used plastic coating, but it also makes a great alternative to plastisol. If you're looking for a coating that's strong and flexible, then it's a good idea to use a PVC coating.

Another advantage of PVC coating is that it's very durable, which means it will last longer in the long run. A PVC coating is great for ultrasonic parts cleaning because it won't corrode if it comes into contact with a hard surface. Unlike with traditional paints, PVC coatings are safe and won't fade. A PVC coating will last a long time and prevent costly reprocessing.

PVC coatings are used in many industries, from automotive to household items. The chemical solutions used in these processes vary in causticity, but a PVC coating will help you protect your products from chemicals. Besides, it also will prevent corrosion on steel. For example, a PVC coating is ideal for applications where temperature and chemical resistance aren't a concern. The materials can also be made of plastics.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.