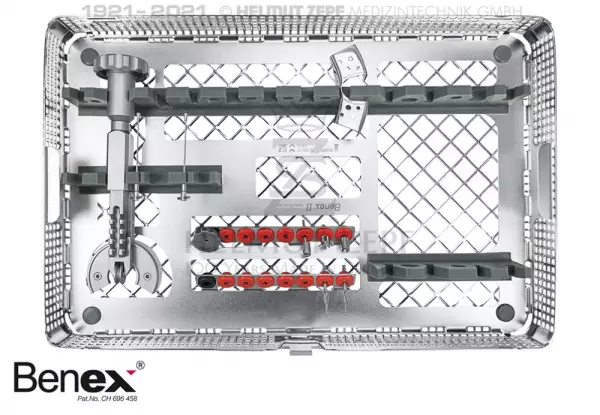

Benex extraction systems and sets - Innovative...

Benex extraction systems and sets - Innovative dental instruments for extraction ...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Benex extraction systems and sets - Innovative...

Benex extraction systems and sets - Innovative dental instruments for extraction ...

CAD construction / development of medical...

CAD construction / development of medical products CAD has supplanted the drawing board and many...

Spine - Instruments & Implants

We develop, optimise and manufacture a variety of spinal implants and instruments (e.g. pedicle scre...

The MIS Z-Pedicle Screw System and the pre-sterilized implants offer surgeons an ideal solution for...

Premium-quality orthopaedic instruments and...

For use in orthopaedics,we offer premium-quality and robust instruments that meet all the deman...

FastExtract® MX – Easy Screw Removal - universal...

FastExtract® MX – Easy Screw Removal - universal screw removal system Who does not know...

Surface finishing the perfect finish for...

Surface finishing - the perfect finish for your products Manufacturing sophisticated products is...

Orthodontics - skeletal anchoring in orthodontics

An important prerequisite for successful orthodontic treatment is the sufficiently stable and resili...

Implants and implant systems dental

Implants and implant systems dental With SonicWeld Rx® we have developed a revolutionary proc...

Titanium Anodising Type III color anodising...

TYP-III colour anodising - colour anodising makes the difference TYP-III colour anodising covers...

Of course, there are special requirements for implant production, especially when it comes to larg...

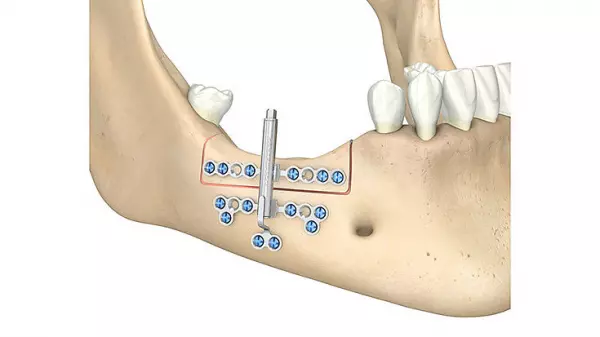

CMF Dental Micro Screws + Instruments +...

47.573.04S STAINLESS STEEL, MICRO SCREW, Ø 1,0 X 4MM , PHILLIPS, GREEN ID-PLUG (PACKAGE UN...

The main problem with implants screws is that they can become loose. The reason for this is that the threads of the abutment or implant can become contaminated with blood, saliva, or other peri-implant fluids. The resulting loosening of the implant screws will affect the overall appearance of the teeth. Therefore, a professional needs to perform a careful inspection of the implants screws to avoid the occurrence of loosening.

The screw can loosen due to internal thread damage. Some authors advocate drawing the fragment further into the implant body and re-tapping the threads above the fragment. Various methods are employed for retrieving the screws, including custom-made drill guides made from a conventional impression post. In a recent study, Yoon and colleagues converted a conventional impression post into a fork-shaped drill guide by soaking it in an auto-polymerizing resin. The converted post can be positioned over the implant without a screw, and the space through it is a channel for rotary instruments.

Tightening implant screws requires a specific amount of torque. The torque required for each type of screw depends on the shape and material of the implant and abutment. As the torque is increased, the coupling force increases and the prosthesis-implant system is more stable, but the excessive torque can cause the screw to loosen or fracture. The recommended torque depends on the mechanical properties of the screw and the friction coefficient between the two parts.

As mentioned before, the torque required to tighten an implant screw is important. Failure to do so may result in the fracture of the screw. Several articles have been published on various techniques to retrieve a broken implant screw. However, these methods are not intended for use in clinical practice. The best technique is to follow the manufacturer's instructions and ensure that the screws have the right torque to remain secure. When the patient is not able to perform the procedure, the clinician must remove the broken implant screw.

A good quality screw is important. A poorly-fitting screw can cause the implant to fall out of place. If this happens, the patient should take the implant to a dental professional for replacement. This is the best way to avoid loosened implants. They should be checked regularly to prevent loosening. It is important to visit your dentist for a check-up every six months. A dentist must check the implants regularly. It is essential to have them replaced at least once a year.

The screw is usually permanently fixed. During this time, the patient needs to be able to remove it properly. The screw must be extracted with a tool. The OPERACE was developed in collaboration with orthopedic implant manufacturers and doctors to provide an easy and fast way to remove screws. This tool is equipped with interchangeable inserts for different types of implant screws. Depending on the type of screw, it can be removed from the shaft or the cancellous bone.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.