Prototype technologies for medical technology

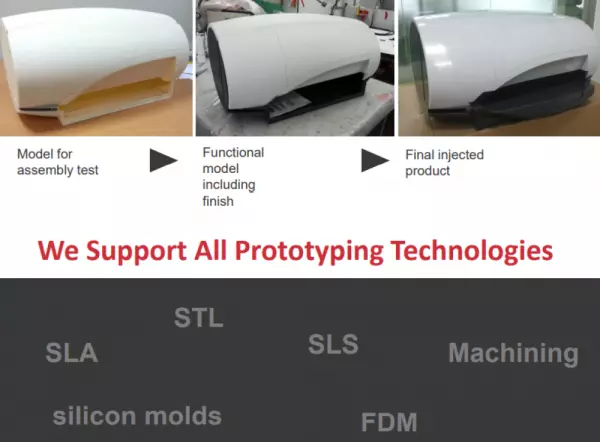

Medical technology Prototyping High quality prototyping is a critical stage in the product developm...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Prototype technologies for medical technology

Medical technology Prototyping High quality prototyping is a critical stage in the product developm...

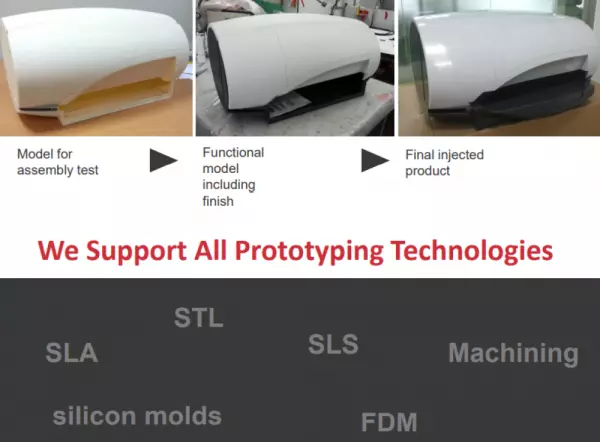

The process of selective laser sintering (SLS) involves fully melting and fused particles of raw materials. This method is ideal for the production of high-precision low-volume parts, such as aerospace and automotive parts. SLS machines can produce a variety of complex and intricate parts from a wide range of materials. The benefits of SLS include increased reliability, lower cost, and easy setup.

The first SL3D printer was produced in 1989 by Deckard and Beaman at the Desk Top Manufacturing Corporation. This company developed stereolithography and later sold its technology to 3D Systems. These technologies have been used for thousands of years to create everyday objects. Today, these devices are highly affordable and can easily be used in a variety of applications. The main benefit of these additive manufacturing machines is that they can make complex parts in very little time.

The SL3D printers have a great number of advantages. This process is ideal for rapid prototyping and production. One of the most interesting benefits of SLS is its ability to produce a high-quality object quickly and cheaply. The process is also flexible and offers a large number of materials and finishing options. The resulting product can be used as a prototype or as an industrial part.

The process of SLS is very flexible and versatile. It can be used on a variety of materials, including metals, plastics, and glass. SLS 3D printers can also be used to create components. A recent study by a team at Northwestern University found that sintering the whole model is faster than the method of fusing individual metal particles with a laser. It also increases the structural integrity of the model, since the entire model is still flexible before it is sintering.

SLS 3D printers can produce complex parts with interior components and without affecting the surface of the part. SLS printers have many advantages, and they're especially useful for prototypes and small-scale production. They can also reduce manufacturing costs and downtime and can produce prototypes quickly. Moreover, SLS printers can be customized for various applications. If you're looking for a custom-built product, select a SLS-based SLS model that suits your needs and budget.

In addition to a streamlined process, SLS 3D printers are also easy to use. They do not require tools or supports, which makes them an excellent choice for any manufacturer. The printing process allows for a variety of materials and applications. This means that SLS printers can be used to create various types of functional parts in a wide range of industries. The advantage of SLS printers is that they can be very versatile.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.