We refine surfaces A turned, milled and even ground surface is often not fine enough to meet the...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

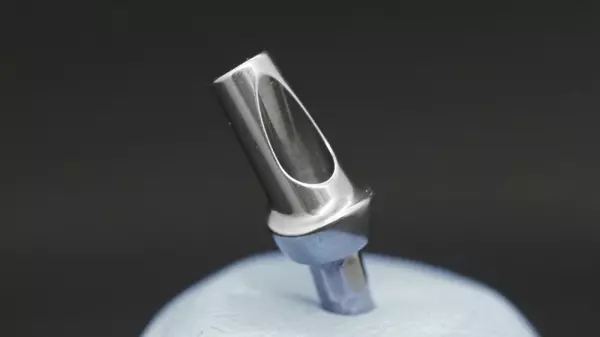

Finishing processes for implants

Knee joints, hip joints, dental implants, bone plates and bone screws Homogeneous, smooth implant...

Finishing processes for dental

Denture clasps, dentures, braces, mouth splints, partial denture plates, implants and prostheses...

Finishing processes for hearing aids and...

Earmoulds and in-ear headphones Earmoulds are manufactured using additive or cutting processes wh...

OTEC can generate extremely flat surfaces through mass finishing, surfaces which are perfect for bea...

Surface treatment - Tibia, femurshaft, pan...

The workpieces are clamped and processed with special brackets. Ra values down to 0.01 µm can...

Finishing processes for medical instruments...

Scissors, handles, drills, clamps, endoscopes and turned and milled parts Medical instruments and...

Small and micro parts are used particularly in medical technology. The surfaces that are achieved on...

Finishing processes for tablet tools

Tablet tools must be polished because the abrasive pressed powder reacts with and roughens their sur...

The process of micro vibratory grinding involves the use of vibration to smooth surfaces and removes visual defects. The process can be used on parts ranging from a few millimetres to several kilograms. This technique is effective in removing burrs and sharp edges from metal and plastic components. The machines are versatile, and can work with parts weighing a few grams to several tons. The materials that can be processed in this way include ceramic, plastic, and metal.

Micro vibratory grinding is an effective method of deburring and resurfacing metals. The vibratory action results in a high gloss finish on metals, but the production time is longer. Small media are ideal for polishing and deburring small parts. They can also be used to round and radius sharp edges. Both types of media have their own advantages. The smallest media are generally gentler and more suitable for fine-finishing processes. The larger sizes are more aggressive and allow for faster removal of burs and sharp edges.

Micro vibratory grinding can produce a high-quality finish, but the process has a few drawbacks. First, the small-sized media require slower processing. Second, the large media can produce a rougher surface, but the large-sized media lend themselves to more aggressive grinding. The large-size media is suitable for polishing and deburring, but can also be used for radiusing sharp edges. So, it's important to understand the limitations of micro-vibration machinery.

Lastly, micro vibratory grinding is often more suitable for delicate parts and tight-tolerance projects. This process can achieve a higher-quality surface finish without excessive surface wear. The result is a smoother surface with reduced corrosion initiation sites. The method requires less time and labor than other methods. However, it is not for everyone. The results are worth the extra cost and time. So, don't wait to start micro-vibratory grinding for your next project.

The most important advantage of this type of grinding is its ability to remove large amounts of metal from parts. Because it uses a high-frequency oscillation, this process can be used on very small parts. Its smooth surface and small particle size can also make microvibrations more effective. This method is highly versatile and can be used for any type of material. These tools are also very useful in the production of complex products. It is a great choice for those who don't have enough space for a conventional grinder.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.