Particle suction extraction C|PS² in combination with shortened direct analysis PartSens 4.0

In production processes, it is increasingly important to be able to quickly measure and evaluate cleanliness in the process. This means that targeted measures can be taken immediately if the required cleanliness values are no longer met. Among other things, rapid cleanliness analysis is important for monitoring and optimizing cleaning processes.

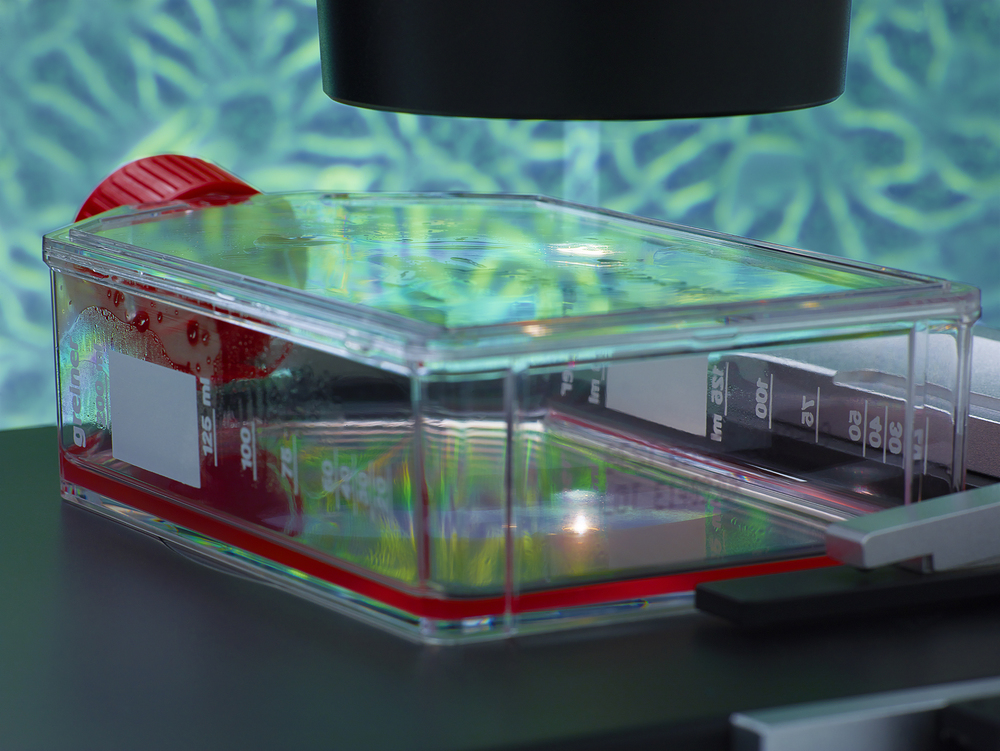

With the dry extraction method, the test procedure with the particle suction extraction C|PS² offers the ideal basis for the shortened direct analysis using the PartSens 4.0 surface measurement system from PMT particle measurement technology GmbH. The analysis pads for the PartSens 4.0 direct analysis are integrated into the C|PS² suction extraction system via the special analysis pad holder. The optimal testing of highly sensitive components takes place within a laminar flow environment, which is made possible by the mobile structure of the extraction system. With suction extraction in the laminar flow environment, the particle contamination is sucked off the component with the lowest possible blank value and the extracted particles are deposited on the adhesive analysis pad.

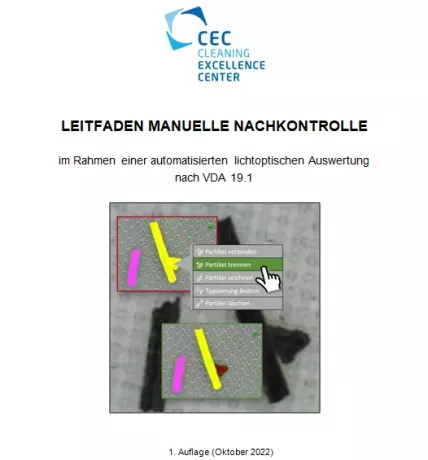

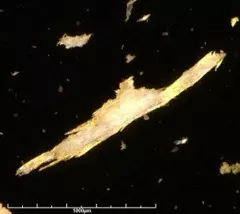

The analysis pad is then inserted into the PartSens measuring head and into the PartSens 4.0 and the 5-fold series measurement is started. The results of the 5 series of measurements are summarized and output as an overall result. The measurement result comes very close to the light microscopic analysis according to VDA 19.1. In addition to measuring the particle length as Feret max, the PartSens+ 4.0 offers the possibility of differentiating between particle sizes and particle numbers of metallic and non-metallic particles and fibers.

C|PS² in combination with a shortened direct analysis PartSens 4.0

To the original article