A lot of recurring standard work in everyday medical laboratory work is still only partially automated with additional manual work, for example blood group determinations or antibody tests. If modern medical-technical laboratory analysis systems are used instead, a huge savings potential opens up. Its special design enables continuous, fast and reliable laboratory work with only a small number of staff and more security in the diagnosis. It goes without saying that the systems comply with the relevant safety requirements in terms of function and evaluation. Analysis unit, computer and drives are adapted to the demands of continuous medical use

STRATEC Biomedical Systems AG plans, develops and produces fully automatic analysis systems especially for use in clinical diagnostic laboratories. They integrate dispensing, incubation and washing technology for all necessary work steps, right through to complex liquid handling systems. The associated embedded and PC software, including the approval documentation for the systems, is also created in-house.

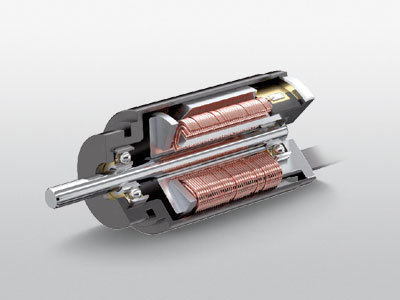

The special challenge in the field of liquid handling is the fast and precise control of many positions, eg on micro or spot plates. A major difficulty lies in the dynamics of the process. The comparatively high masses of the moving actuators, weighing one to three kilograms, have to be accelerated and decelerated quickly. Speeds of up to 1 m/s can be mastered safely and precisely. Exact and repeatable positioning is crucial for the function. In order to be able to approach different plates or sample magazines in a targeted manner, freely programmable positioning is a prerequisite. It goes without saying that all safety regulations and EMC regulations applicable to medical equipment must be observed by the electronics and the highly stressed drives. The mechanical drive must also reliably ensure start-stop operation in continuous use.

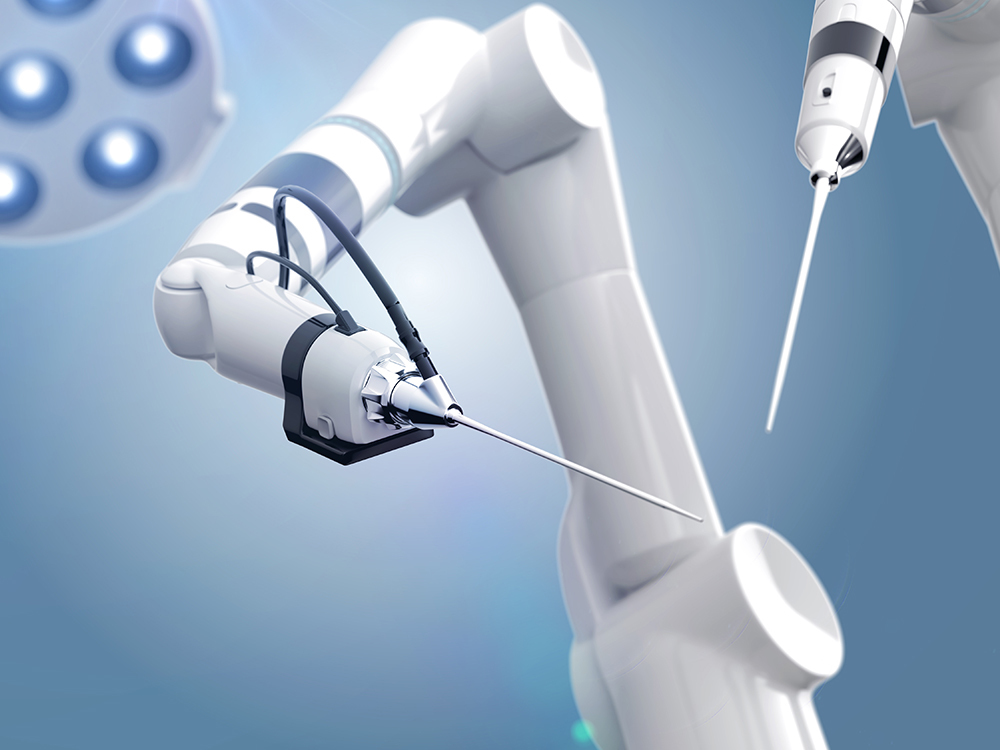

In virtually every major hospital, testing is standard during medical procedures. The medical laboratory carries out these analyses. Due to the number and nature of the tests, many steps and samples or reagents are required. For sample preparation, distribution, dilution series or addition of reagents in a laboratory, several hundred precisely dosed and precisely applied liquid additions can be required without any problems. Executed by hand or semi-automatically, this requires a great deal of attention and reliability from the staff. If these tasks are carried out fully automatically, the standardized micro and spot plates or cuvettes already used can also be treated mechanically with the processes required in each case. The precise and reliable mechanics of the analysis system work tirelessly at the same speed without any breaks. This increases the reliability of the findings and increases the efficiency in the laboratory. Flexibility is key when it comes to mechanical design and control, because the requirements for sample preparation vary greatly depending on the analysis. In general, a sampler arm must pick up the samples or reagents quickly and place them in different small containers that are very close together. The exact positioning of the arm, i.e. the exact allocation of sample and reagent, is decisive for the quality of the analysis. In addition to blood group determination or immunological analyses, biotechnological analyzes can also be processed safely. The laboratory staff only has to use the necessary reagents and samples once and specify the program. In the case of a quick emergency analysis, e.g. for a blood test during emergency operations, some systems can also leave the standard program and quickly determine the individual case data. This ensures flexible operation despite fully automatic operation.

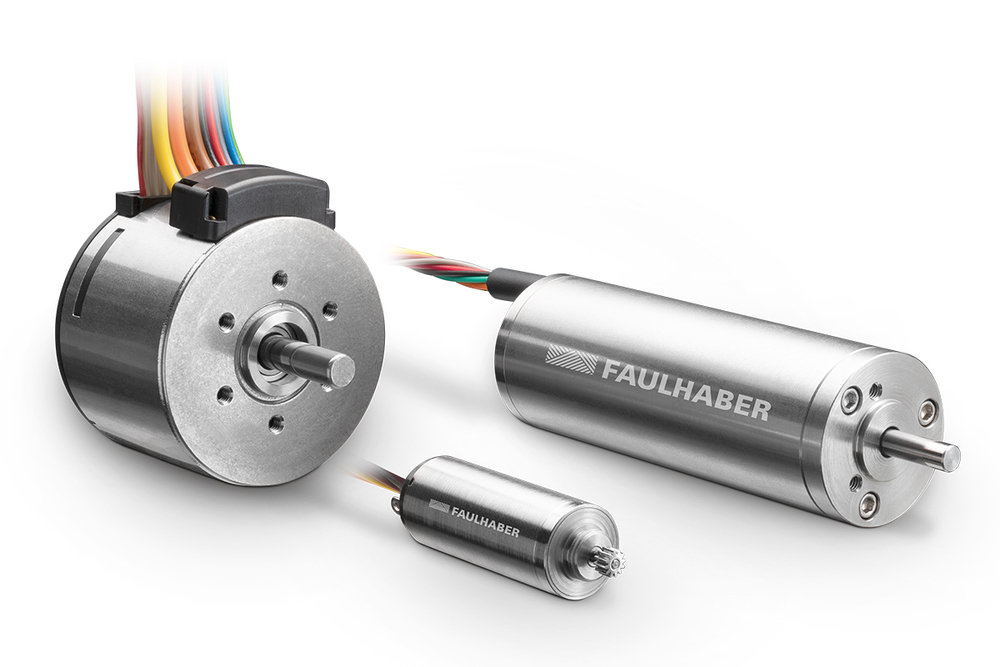

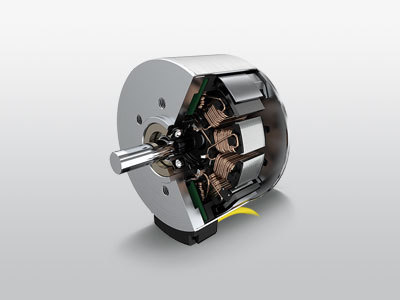

In order to keep the moving masses as low as possible for the dynamic function, only small motors can be used as drive elements. Since the different analysis systems naturally also place many different demands on the optimum drive, it is desirable to have as broad a range of motors as possible. For this reason, the analysis system specialist works together with the small motor specialist FAULHABER. The extensive range of motors, associated gears and encoders for positioning from a single source makes both new developments and standard production much easier. Motors from this program are therefore used in almost all products. Marcus Wolfinger, member of the Stratec board, explains it like this: "The Faulhaber engines