I still remember my entry into maxillofacial surgery very well. Looking back, it was probably a mixture of luck, foresight that there could be a great opportunity in this area, and coincidence.

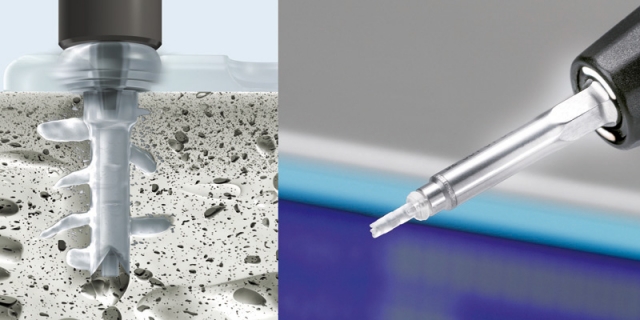

During a shareholders' meeting in the late 1970s, a product manager reported on a professor from Strasbourg who was about to revolutionize oral surgery. He wanted to use plates and screws for the treatment of fractures, as has already been done in other surgical disciplines. You have to know that in maxillofacial surgery back then it was still customary to connect fractures with wire instead of plates and screws and then twist the wire. Due to this procedure, the patients were sometimes unable to consume solid food for weeks and this connection was not really stable either. The professor wanted to change this situation and had already commissioned a French manufacturer to manufacture plates and screws for his purposes. However, he would not be satisfied with the quality of the products.

We agreed at the shareholders' meeting: the idea sounds interesting and we should introduce ourselves as a company in Strasbourg. I was in my mid-twenties at the time and the youngest shareholder in the KLS Martin Group. The other shareholders probably thought I had the least to do, so the choice fell on me. I should meet the professor personally in Strasbourg and talk to him about his idea.

I then traveled to Strasbourg with the product manager to meet the professor: Prof. Maxime Champy.

Prof. Champy explained his method to us and showed us the other company's implants. Prof. Champy's thoughts really grabbed and inspired me back then. I always say that I'm more of an engineer than a businessman and I was really impressed by this technical facet and approach. I realized what this professor is up to is really awesome.

Inspired by the trip, I immediately went back to our production company Karl Leibinger Medizintechnik in Mühlheim an der Donau and, together with our foreman, drew the first drafts of the plates on paper. This resulted in four panels for the time being: the 4-hole panel short, 8-hole panel long, 4-hole panel bent to the left and right. That was all. Incidentally, Prof. Champy is still of the opinion today that all fractures can be treated with these four base plates, although the field has of course changed extremely over the years.

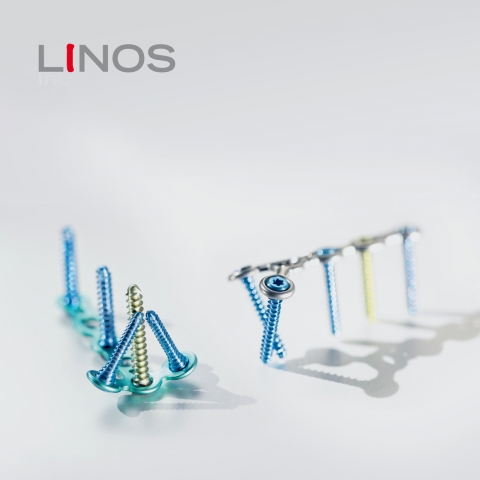

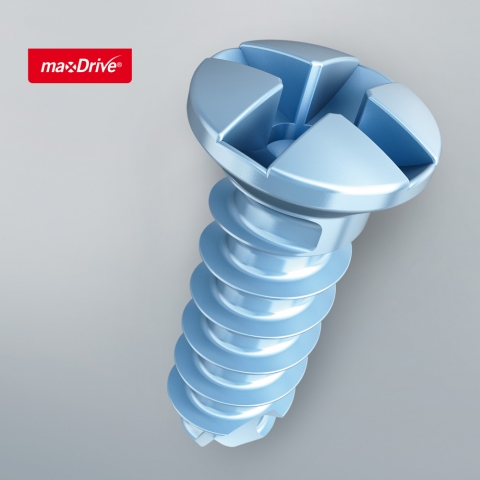

After the production of these standard plates, we also started to develop bone plates, bone screws, screwdrivers, tools to bend the plates and much more for Prof. Champy, who was enthusiastic about our quality. From then on, the range has continued to grow. This new surgical approach was very controversial at first, but it was quickly recognized. In the USA it was known as "rigid fixation". The only difficulty we initially encountered in worldwide distribution was the material. For the purposes of Prof. Champy, in which the implant is removed again after a certain time by a second operation, stainless steel was sufficient. However, if the implant remains in the body, titanium is the better option. It was precisely this switch from stainless steel to titanium that was the breakthrough. To this day, titanium is often the material of choice in the production of our standard and patient-specific implants, even if the choice of different materials has expanded significantly over time and we are constantly researching new materials. I am really very happy that we took this path back then and that I was able to accompany and continue our entry into maxillofacial surgery from the beginning until today together with my son Christian.