Electroplating and P VD services

There are many good reasons to choose PVD technology: in addition to the low chemical loa...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Electroplating and P VD services

There are many good reasons to choose PVD technology: in addition to the low chemical loa...

Higher quality finishing / finishing processes...

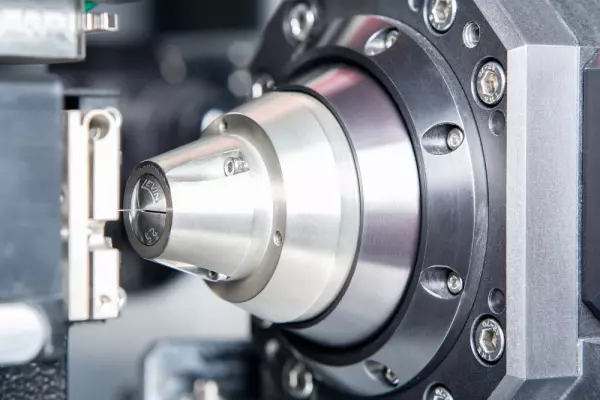

Higher quality finishing / finishing processes of surgical instruments / implants Refining or ref...

Laser technology for the medical device industry

ADMEDES customers benefit from the deep process know-how we have earned since our founding in 1996....

Etching of medical parts, etching of medical components, etching of medical materials, etching of medical products, etching of medical devices, etching of implants, etching of surgical instruments

Etching is a process in which acid is used to create a design on metal by burning a pattern into it. The material is typically zinc or copper, coated with a resin that resists acid. Smoke is sometimes added to the metal plate to give it a unique look. The etching process involves a needle being inserted into the plate through a slit in the sand. This exposes the metal without penetrating it. Once the design has been etched to a depth suitable for the work, the plate is immersed in an acid solution. The resulting lines are removed by a slurry of sodium carbonate.

Etching can also be used in the manufacturing of medical accessories. Surgical staples are etched into a metal plate to be used for surgery. The procedure is faster and less painful than traditional sutures. Pacemakers can also be made with EMI/RFI shielding and chemical etching can be used to make laboratory filters. High Transmission Cellular (HTC) grids are etched into x-ray eyepieces to absorb x-ray radiation.

Etching is a versatile process that allows for the creation of high-quality medical devices. Its versatility makes it the ideal material for medical devices. It is not the only method of metal shaping. In fact, it is a popular choice among surgeons and doctors to produce diagnostic tools. Learn more about photo etching below.

Aside from being used for medical applications, etching is also used for the manufacturing of surgical tools. This method produces parts in a large volume and is capable of making them from biocompatible materials. It is often used for surgical instruments and small components. So, if you're interested in using etching technology to create a medical device, it may be time to learn more about the process. There are several benefits of this technique that make it popular.

In the Medical Industry, photo etching is a powerful tool. It allows surgeons to produce many parts in a single process. It is a process that can be applied to a wide variety of materials, from plastic to titanium. In addition to implants, etching can be used for many different types of biomedical devices. The process is ideal for creating implants and other medical tools. It also produces burr-free edges and blind holes.

Among the most important advantages of etching is its ability to create beautiful designs on metal. It's also an excellent method for manufacturing medical devices made of stainless steel. This process allows the printmaker to control the acid's effects. It is also used for manufacturing semiconductor devices and printed circuit boards. It's also a great choice for artistic purposes. It's versatile. And it's very economical. For example, you can get the same results as in a traditional lithography.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.