After the treatment or manufacturing of metallic workpieces, it is usually necessary to free them of...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

After the treatment or manufacturing of metallic workpieces, it is usually necessary to free them of...

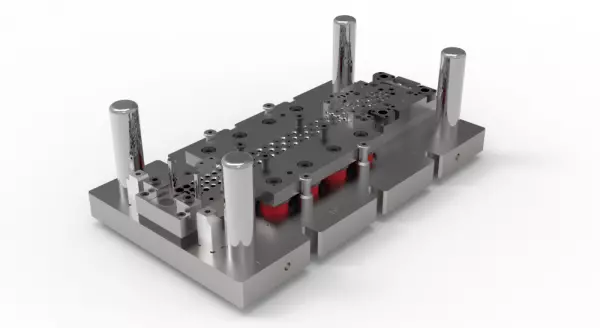

As soon as larger quantities are available, a tool is sometimes indispensable in order to be able to...

Medical Clean room plastic injection

Medical technology clean room injection molding We manufacture plastic components in the clean ro...

The tool making medical industry has a long history. Since the mid-16th century, this industry has been producing tools for the medical industry. Surgical instruments often consist of metal parts, such as staplers used to close incisions. Stamping ensures that all parts of a device fit tightly together and maintain identical tolerances. This manufacturing process is also used to make backup parts that hold the same tolerances as the main tool.

The medical industry uses various types of tools, ranging from soft tooling to hard tooling. Soft tooling involves punching holes, slots, tabs, and other features with a press brake. The cost of a soft-tooled part ranges from $75 to $500, but can increase to $2,000 or more for more complex parts. This technique is generally used for prototyping or low-volume orders, but can increase the overall cost per part.

The medical industry uses soft tooling to produce low-volume parts. This process involves punching holes and slots, forming tabs, and bending the piece with a press brake. Soft-tooling typically costs $75-500 per part and can cost upwards of $2,000-3,000 for more complex parts. This process works for low-volume orders and prototyping, but can add significant cost per part. However, it is important to consider all of the costs associated with this process before making the decision to use this method.

Using soft-tooling for the medical industry is a common method of low-volume part production. In this method, dies are punched and fabricated using a press brake. This method generally costs between $75 and $500 per part, but can exceed three thousand dollars for more complex parts. It is often used for prototyping. The complexity of the parts means that the cost per part is considerably higher. The time it takes to make each individual component is considerably higher.

The medical industry uses precision tools. These tools are designed to minimize errors and maintain proper functionality. Besides machining, the medical industry also uses progressive dies. The use of progressive dies is an important component of the tooling process. Moreover, it reduces costs per part in the medical industry. These precision dies are made using custom-designed and unique components. Many OEMs find that contract metal fabricators significantly reduce their cost per part.

In addition to the hard tools, soft tools are also used for moulding. For instance, a medical industry tool is used for moulding. A mould is a mold that is made of material. Micro endmills are useful tools for the medical industry because they cut the material. In this way, the tools are often highly durable and long-lasting. The tools are also required for different types of parts, such as implants.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.