Time equals money when turning an idea into a marketable medical device. To accelerate your journey...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Time equals money when turning an idea into a marketable medical device. To accelerate your journey...

Laser technology for the medical device industry

ADMEDES customers benefit from the deep process know-how we have earned since our founding in 1996....

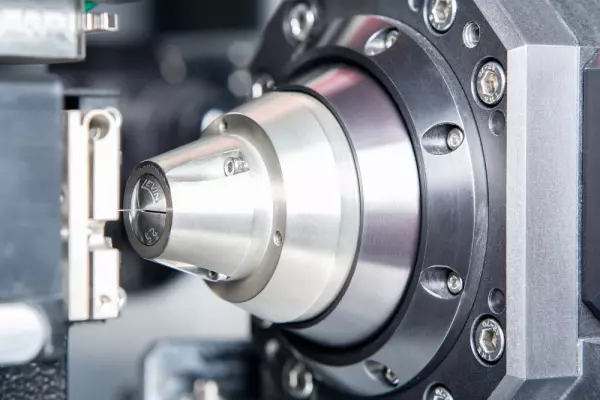

There are two types of laser cutting machines. One is stationary and the other one is portable. Both of them can cut a variety of flat materials. A stationary machine will be most useful for cutting wood and plastics, as well as thin metals and soft materials like rubber and foam. The main difference between these two machines is the type of energy they use. The CO2 laser is most effective for cutting wood, and the Nd-YAG laser is most effective for cutting metals.

The power density of a laser cutting machine is achieved through the laser focusing mechanism and controlled by the computer. The output of a laser is a high-frequency, repetitive pulsed laser. This beam is reflected and transmitted through an optical path. The focusing lens group focuses the light on the object to be processed. This pulse instantly produces a small hole in the processed object. This spits out the material.

Another important component of a laser cutting machine is its wavelength. The wavelength refers to the spatial length of the complete cycle of vibration for a single photon in a beam. The wavelength determines how quickly a material will be heated or melted by the beam. Moreover, the laser's mode affects how effectively it cuts material. It's ideal if the intensity distribution of the beam is Gaussian. This will ensure a clean and consistent cut.

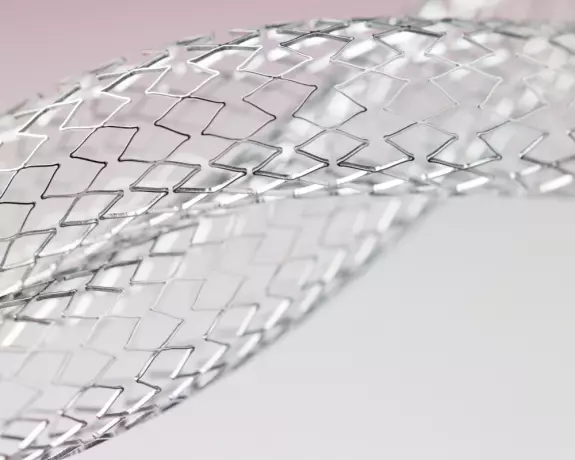

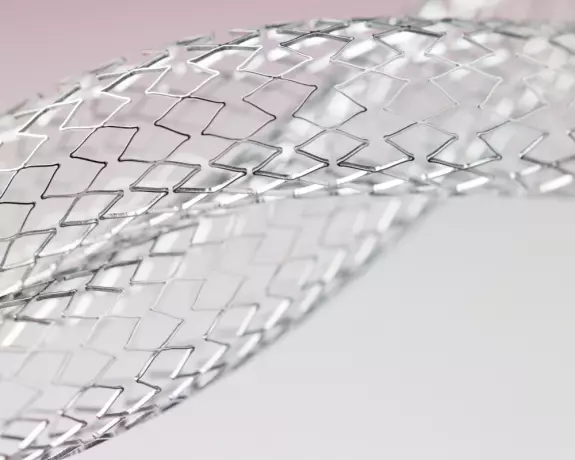

NPX Medical uses a variety of post-processing options for the parts that are cut. The machine shown here is used to cut T316 stainless steel with an O.D. of 5 mm and a wall thickness of 0.254 mm. The left side part is electropolished, while the right side part is as-cut and micro-blasted. Once the material is cut, the post-processing process will be applied to further improve the finished product.

The medical industry has become increasingly automated. Medical devices are often made in limited batches with customized designs. For this reason, flexibility and ease of use are essential. Some are created from tube blanks, while others require precision machining of flat stock. In these cases, the same machine must be able to handle both types of material. A good quality laser cutting machine should feature multiple axes of CNC-controlled motion. The HMI must also be user-friendly for a surgeon.

High-volume medical components can be made using a laser cutting machine. It is also possible to manufacture catheters with a laser-cutting machine. A laser-cutting machine can also contribute to the surgical precision. It can help doctors create precise cuts, which in turn can speed up the procedure and speed up the recovery period of the patient. The mechanical part of a laser head has no contact with the workpiece, making it ideal for this application.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.