1 - 5 by 5 results

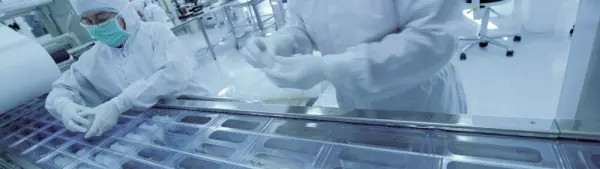

Healthcare & Medical assemblies

We are the reliable partner covering all areas from conception to (sterile) packaging of the finishe...

Assembly and final inspection of medical...

Assembly and final inspection of medical products Eurofins Inpac Medizintechnik GmbH assemb...

We are service providers in the areas of turning, milling, water jet cutting and the additive manufa...

Contract Packaging and Sterilization for...

Contract Packaging and Sterilization of Medical Products From raw material to ready-to-...

1 - 4 by 4 results

Manual assembly

When it comes to the assembly of medical devices, manual assembly is the best option. While it is a tedious process, it is often the only way to achieve the quality of the end product. It is also more economical, especially in low-volume production. Many components require manual assembly, so it is important to specify these requirements when choosing a manufacturer. This way, they can ensure the final product is as accurate as possible. In addition, it is possible to automate some processes to make the job easier for your team.

While the use of automation is an obvious improvement for many manufacturing companies, manual assembly still has some advantages that are important for the business. Human workers can identify defects more quickly than machine-made counterparts. Another advantage of manual assembly is that it is flexible. The workforce can easily ramp up and down production volumes. And it can be adjusted whenever needed. The benefits of manual assembly are endless. But before making the switch, read on to learn more about how this technology can benefit your business.

Manual assembly is an ideal solution for low-volume orders with unique components. This method is especially beneficial for small-scale productions that involve fewer components per board. Furthermore, human workers can spot defects and other flaws more quickly than machines. Additionally, it is more flexible and allows for quicker changes. With Drishti, you can automate assembly tasks using data and analytics, and you'll have complete visibility over the whole process from beginning to end.

While manual assembly might not be the best option for every project, it has its benefits. For example, in the medical industry, manual assembly is a crucial part of the process. In addition to improving worker safety, this method also lowers labor costs. It allows for shorter cycle times and lessens cycle times. The new system helps you reduce labor costs and cycles by up to 30%. If you're looking to automate your assembly processes, Staubli is the right choice.

As the medical device industry continues to change and expand, the assembly methods will need to evolve. This means that the manual method of assembly will be obsolete in a few years. The best automated method is the one that allows for the continuous integration of different parts. This will not only increase the productivity of the manufacturing process, but it will also ensure the safety of the workers. This type of automation will ensure a high quality product. If you are considering manual assembly for medical devices, you should consult with industry professionals to find out what they recommend.

The benefits of manual assembly depend on the application of the process. If you need to produce a small quantity of medical devices, it may be worth considering automating the process. It is less expensive and can also reduce the risk of human error. However, the downside is that human error can affect the quality of the products. If you're looking to produce an item with a precise specification, then automatic assembly is a better option. It doesn't have any limitations and has fewer risks.