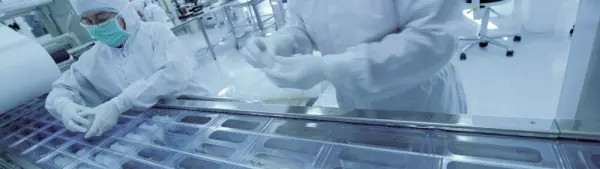

Medical Clean room plastic injection

Medical technology clean room injection molding We manufacture plastic components in the clean ro...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Medical Clean room plastic injection

Medical technology clean room injection molding We manufacture plastic components in the clean ro...

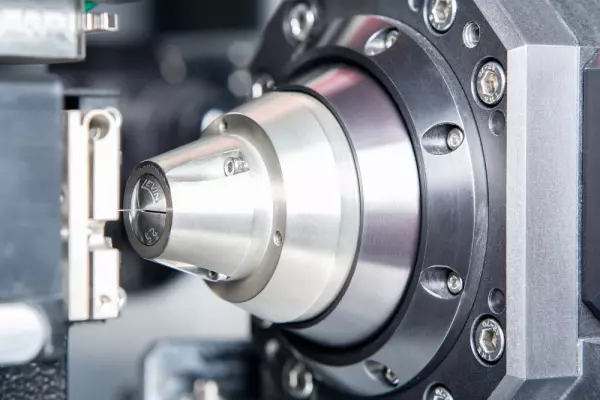

Milling technology / milled parts - contract...

Milling technology / milled parts - contract manufacturing for medical products Milling refers to...

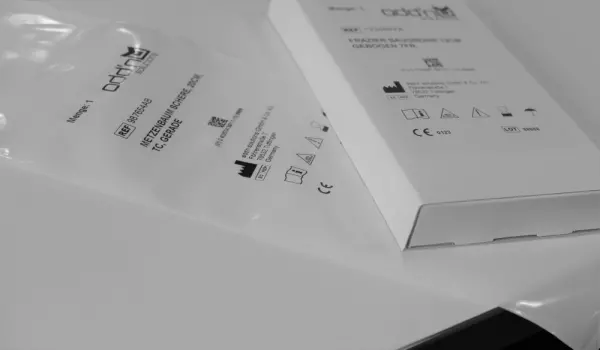

Packaging of surgical instruments

Finding the right packaging for the multitude of surgical instruments, but also for products from ot...

Packaging of medical products under clean...

Packaging - packaging design Packaging of medical products under clean room conditions ISO clas...

Electroplating and P VD services

There are many good reasons to choose PVD technology: in addition to the low chemical loa...

Healthcare & Medical assemblies

We are the reliable partner covering all areas from conception to (sterile) packaging of the finishe...

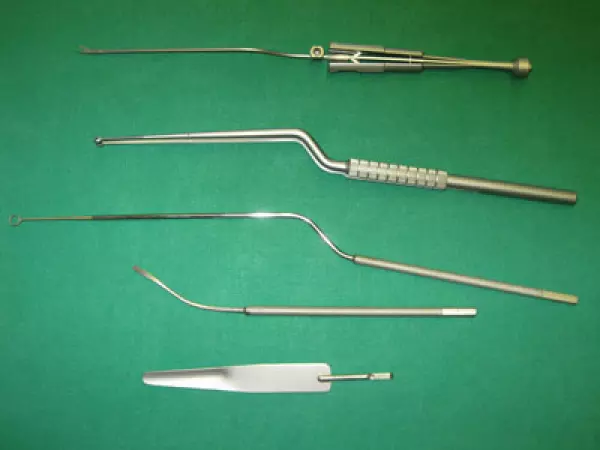

Repair service and maintenance of micro instruments

We repair MIS instruments from all well-known manufacturers , drive systems such as drilling hoses,...

Purity is the top priority in medical technology. This is why the filtration of process liquids such...

We are service providers in the areas of turning, milling, water jet cutting and the additive manufa...

Development of optimal packaging for medical...

Development of optimal packaging for medical products ENGINEERING In the contex...

Work aids, assembly systems Designed for small quantities and high variance: our winding system f...

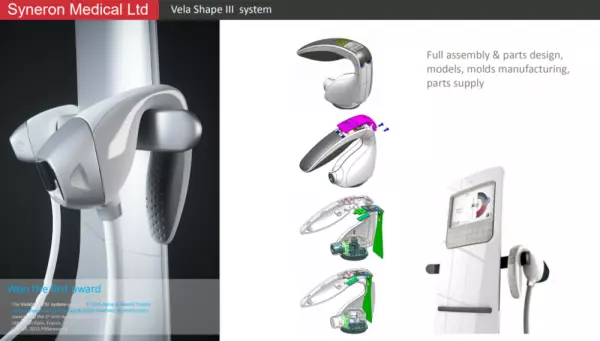

Medical technology laser dermatology, body...

LASER DERMATOLOGY, BODY SHAPING Hardware MPE / Rimoni offers LASER DERMATOLOGY for medical technolo...

Packaging of medical products in hard and...

Packaging - packaging design Packaging of medical products in hard and soft blisters under clea...

Cleaning, packaging and storage solutions...

Our offer to you! We offer cleaning, packaging and storage solutions for components from the medi...

Assembly and final inspection of medical...

Assembly and final inspection of medical products Eurofins Inpac Medizintechnik GmbH assemb...

Research & development in the field of...

Do you have a product idea in the field of medical technology and need support with development?...

Contract Packaging and Sterilization for...

Contract Packaging and Sterilization of Medical Products From raw material to ready-to-...

Upper basket for optimal accommodation of...

100 Upper basket for optimal accommodation of injector modules or inserts Upper basket with...

Laser technology for the medical device industry

ADMEDES customers benefit from the deep process know-how we have earned since our founding in 1996....

Global regulatory agencies such as the US FDA and the European Commission have issued strict guideli...

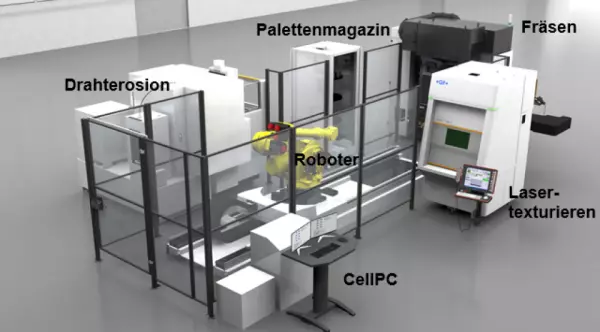

Automation / zero point indexing systems

Various automation solutions, integrating GF machines as well as other brands, combined with other p...

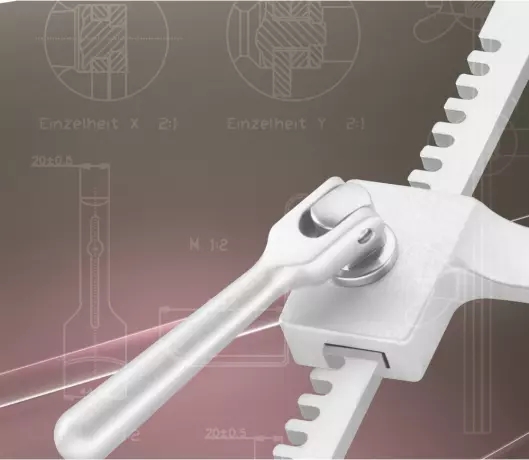

Our speciality: custom-made products You have a new idea or need an instrument solution for speci...

Packaging validation according to DIN EN...

Validation Packaging validation according to DIN EN ISO 11607-1 and 2.

Transport trolley for loading and unloading...

MF/3 transport trolley for loading and unloading cleaning and disinfection machines For easy handlin...

Production and design of packaging for medical...

PACKAGING DESIGN Blister design Along with standard blisters for product packaging and transpo...

Stent production as series applications Thanks to our handling, it is possible to remove stents fro...

Production / contract manufacturing of medical...

Production / contract manufacturing of medical products on behalf of customers Since our foundati...

Higher quality finishing / finishing processes...

Higher quality finishing / finishing processes of surgical instruments / implants Refining or ref...

Products and services from the categories Assembly and packaging of medical products in medical technology or other healthcare-related industries .

Products and services from the categories Assembly and packaging of medical products in medical technology or other healthcare-related industries .

Assembly of medical products, packaging of medical products, assembly of dental products, packaging of dental products, assembly of laboratory products, packaging of laboratory products

Manufacturing and assembly are the final steps before a finished product can be shipped. These processes are necessary for virtually all consumer products and a large percentage of industrial products. The process of packing begins with raw materials and ends with labeling requirements. Most goods that are manufactured must be packaged before they are shipped. In addition, some types of assembly require heavy processing. Regardless of the type of assembly required, it is crucial that the final product is properly packaged and shipped.

SHL Group's team of experts has a deep understanding of the needs of the medical device industry. This approach has helped them develop a simple solution for the final mile of development. While SHL Group has extensive experience in medical device design, they have also invested in a contract manufacturing service. Their contract manufacturing service offers full turnkey solutions for medical devices and offers a shortened timeline from design to clinic. In addition, SHL's flexible approach to manufacturing reduces the cost of product development, and a more efficient delivery time to market for the clinic.

Excel's medical device manufacturing and packaging expertise allows us to meet ISO quality standards. The company's cleanrooms are regulated to ensure sterility and compliance with regulatory requirements. Our skilled assembly team ensures that each device is clean and free of contaminants. All of our cleanrooms are ISO certified and maintain ISO 8 levels of cleanliness. They can provide a complete kitting and labeling service for a medical device. You can rely on Excel to deliver your products on time.

Forefront's blow molding capabilities include medical grade PVC and vinyl elastomers without DEHP. SHL's high-tech facility is located near several international airports, with optimized materials flow processes. The entire process ends with shipping the finished product to partners. The company's team works with a global supply chain, which means that they can meet any deadline. The engineers also perform tensile, melt flow, and dimensional verification tests.

Aside from manufacturing, the assembly and packaging process is essential for a successful product. It is crucial to have a well-organized workflow that allows employees to be flexible and adaptable. Once a product has been assembled, it will be shipped to customers and/or distributors. This process requires the right infrastructure, which is key. The packaging team should be able to accommodate the growth of the company. The production team should have the capacity to scale for future needs.

Automated assembly processes are best for products with low-mix and high-volume requirements. These machines are fully automated and need no human input. Using an automated process will reduce costs and increase efficiency. This will help you save money and make better decisions about your products. Once you've built your manufacturing process, the next step is to design the packaging. The assembly team will then take the final product to the next stage. Aside from the end-product, your customers will love the finished product.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.