Round wires, flat wires, micro-profiles

ROUND WIRES WITH OXIDIZED OR OXID-FREE SURFACE NITINOL FLAT WIRES MICRO-PROFILES, REEL TO REEL...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Round wires, flat wires, micro-profiles

ROUND WIRES WITH OXIDIZED OR OXID-FREE SURFACE NITINOL FLAT WIRES MICRO-PROFILES, REEL TO REEL...

Best Steels for best knifes: 1.4116 or 1.4034

No question: A good knife needs a good blade. It follows: a good blade needs a good steel. High-qual...

If in the general Surgery, Laryngoscopy, Arthroscopy, plaster (of Paris), ENT surgeon or gynaecology...

EUROFLEX offers customers our expanded line of medical components and new, custom designed solutions...

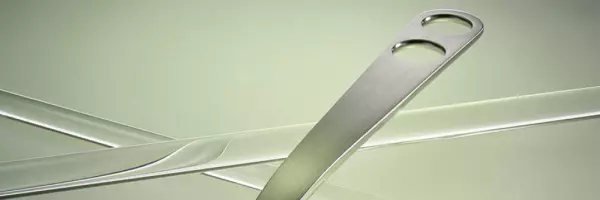

Orthopedic Products - Inserting Tools

The product range of cutting tools in the field of orthopedics includes: Phillips blades...

Manufacture of standard surgical instruments

Standard production Our classic product range includes over 800 active articles, which are used i...

Surgical instruments for proctological applications

Proctology We manufacture a wide range of different surgical instruments for proctological applic...

Spine - Instruments & Implants

We develop, optimise and manufacture a variety of spinal implants and instruments (e.g. pedicle scre...

If you have any questions, we are at your disposal with our sales team sales@medical-bees.de. Or cha...

High-tech steel for surgical instruments

In the medicinal field, materials are used that should all optimally correspond to the specific area...

Stainless steel is the metal of choice for surgical instruments, but it's also used in other applications as well. The main ingredients in stainless steel are iron, nickel, and chromium, which all affect the material's behavior in various ways. Some people are allergic to chromium, while others are intolerant to the metal. No matter which type of instrument you choose, you should be sure to read product labels to ensure that it is safe to use.

Surgical instruments are often made from stainless steel. Stainless steel is not easily stained, and it doesn't corrode in corrosive liquids. Unlike steel, stainless steel also has a smooth surface, making it easy to clean. Unlike rusty metals, stainless steel doesn't harbor bacteria, which makes it ideal for surgeries. However, stainless-steel instruments are more expensive than their counterparts.

Stainless steel is also a good choice for surgical instruments, as it is highly resistant to staining and corrosion. Stainless steel is shiny and easy to clean, and it will not corrode if a surgical procedure is performed on it. Another benefit to stainless-steel instruments is that they will not rust or stain, which makes them more convenient to use. And because they can withstand high levels of abrasion, they will last for many years.

Stainless steel is the most common metal used in surgical instruments. It's inexpensive and abundant. Titanium is next. It's strong and fuses easily with bone. Tantalum is a relatively new material used in surgical instruments. It has properties that make it a perfect surgical tool for various procedures. The price of titanium instruments is also very low, making it a popular choice for orthopedic surgeons. But before choosing an alloy, be sure to look at its use-case scenario.

Stainless steel is an inexpensive material. But it's also prone to corrosion. Stainless steel is a good choice for instrument manufacturing. Besides being able to resist corrosion, it also offers excellent strength. Its advantages include: * Stainless steel is a low carbon steel. Unlike other metals, it is not corrosion-resistant. 304, 316, and 302 have excellent corrosion-resistance.

Stainless steel dental instruments are more expensive than their counterparts, but they are better at resisting corrosion. They have a thin oxide layer that protects them from rust and other harmful substances. The higher the chromium content, the better the corrosion resistance. Stainless steel instruments are more durable than the cheaper alternatives. So they should be made of the highest quality. In addition to these qualities, they also have a long lifespan.

Stainless steel is also available in various grades, and their price varies from cheap to expensive. Mid-grade surgical instruments are made of Japanese stainless steel. They are the next step up from floor-grade quality. Stainless steel instruments are used in surgical procedures to reduce infection risk and ensure a more sanitary environment. For this reason, the quality of these instruments is very important. You should consider the materials they are made of and how they are manufactured.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.