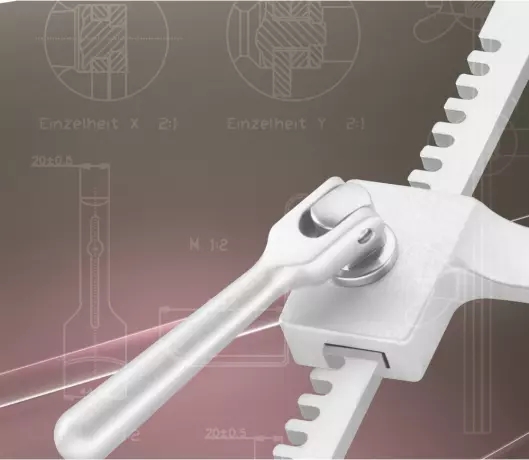

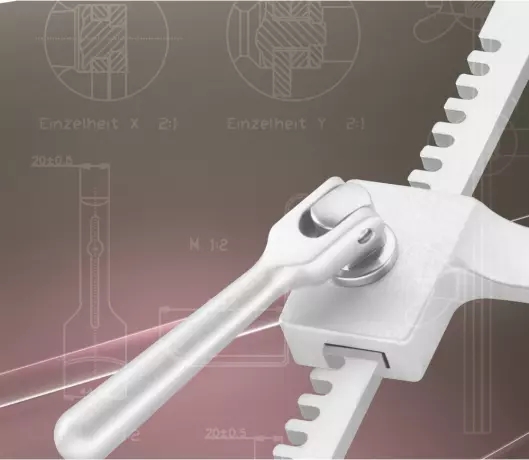

Our speciality: custom-made products You have a new idea or need an instrument solution for speci...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Our speciality: custom-made products You have a new idea or need an instrument solution for speci...

With modern equipment, we can label your products precisely and in a validated manner. To implement...

UDI code verification according to ISO15415...

Verification means providing evidence that a fact is true. Using the UDI code verification in accord...

UDI-compliant laser marking of medical devices, UDI-compliant laser marking of surgical instruments, UDI-compliant laser marking of implants, UDI-compliant laser marking in medical technology, UDI-compliant laser marking in dental technology, UDI-compliant laser marking in the healthcare sector

With the use of in-house laser capabilities, Lucid Group can meet the regulatory demands for unique device identification and indelible marking. The company, based at Manchester Science Park, has been a leading innovator since 2002, with a focus on pharma and hazardous environments. To learn more about how Lucid can help your business, contact us today. We'll provide you with the right solution for your UDI-compliant marking needs.

TRUMPF can supply you with a complete UDI-compliant laser marking solution that can meet all of the EU's requirements. Its visionLine Mark image processing capability is also able to recognize UDI content. Its quality assurance capabilities are a key benefit. Moreover, the technology is passivation-resistant, ensuring your products are ready for UDI compliance as early as 2020.

With its visionLine software, laser marking can be used to create UDIs on any thermoplastic device component, even if it is coated. It is an ideal solution for medical devices because it produces a permanent mark that is resistant to repeated sterilization and cleaning processes. Furthermore, the high resolution and precision of a laser allows for a variety of part geometries. The system is also fast and cost-effective.

UDI-compliant laser marking can be applied to medical devices to ensure the highest safety and durability standards. It can reduce the risk of errors due to human error. The technique is ideal for the creation of Datamatrix codes, which are 0.5 x 0.7mm. The main disadvantage of UDI-compliant laser marking is its compatibility with stainless steel. Additionally, some metals such as titanium may corrode the UDI-compliant laser marking.

UDI-compliant laser marking is an ideal solution for medical devices. Its advanced features allow the FDA to trace devices more easily and reduce medical errors. Consequently, the use of UDI compliant laser marking is an excellent choice for these medical devices. The process of achieving UDI compliance is relatively simple. In fact, the technology can help you produce a UDI-compliant UDI on any medical device.

UDI-compliant laser marking has several advantages for medical device manufacturers. In addition to its biocompatibility, the UDI-compliant laser marking method does not affect the functionality of the medical device. It is also compatible with a wide range of products, including those with intricate shapes. It is able to mark alphanumeric codes and other graphics, and it can also print barcodes.

UDI compliant laser marking is a great way to comply with the FDA's regulations. UDI laser marking is required for most medical devices, including class II and class III devices. In addition, UDI compliance is required for co-packaged and cross-labeled products. In 2018, Boedeker Plastics, Inc. added UDI laser marking technology to its list of services. Through this process, UDI-compliant laser marks can be produced with high contrast and durability.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.