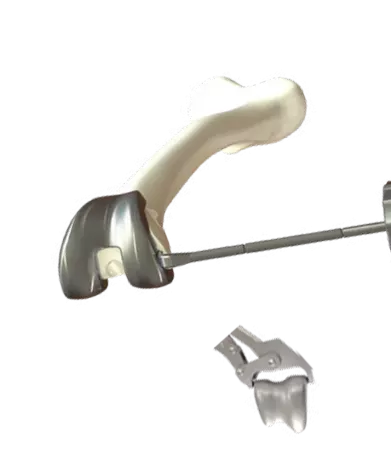

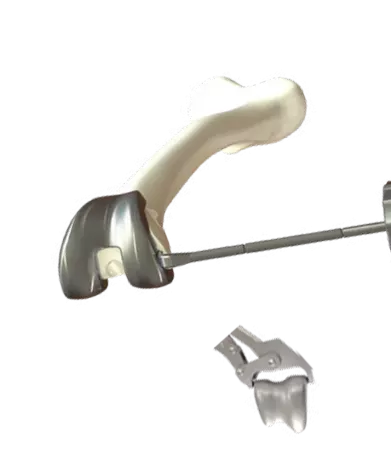

Shukla Knee Universal Knee Implant Removal...

A universal extraction system designed to efficiently remove knee implant hardware manufactured by a...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Shukla Knee Universal Knee Implant Removal...

A universal extraction system designed to efficiently remove knee implant hardware manufactured by a...

Spine - Instruments & Implants

We develop, optimise and manufacture a variety of spinal implants and instruments (e.g. pedicle scre...

Of course, there are special requirements for implant production, especially when it comes to larg...

The VISIONAIRE technology - knee arthroplasty

VISIONAIRE patient-specific instruments for a knee made to measure How can the desire for individ...

EpiFIX™ Growth-Control-Plate - Sterile single-use...

EpiFIX™ Growth-Control-Plate - Sterile single-use kit for growth control A signif...

Instruments and implant systems for osteosynthesis

Plates and Screws for mini, small and large fragments are only a selection from our wide range. With...

Knee implants are used to replace the knee joint in patients with arthritis or degenerative arthritis. Over the years, manufacturers have made improvements to the technology. However, one problem remains: sensors are difficult to integrate into the implant structure. As a result, manufacturers have not been as eager to develop a new device as they once were. Fortunately, this problem is not as difficult as it once was. In this article, we'll look at some of the latest advancements in knee replacement surgery.

Most knee implants use titanium alloys for the metal parts and polyethylene for the plastic parts. Some knee implants are made of ceramic materials or a ceramic/metal combination. These prosthetics are lightweight and easy to place. Surgeons can order a customized cutting guide prior to surgery for difficult cases. These guides are designed to work with various implant sizes and shapes. Although personalized guides may be unnecessary, they can help ensure the best results for patients.

The pros and cons of customized knee implants can be seen in comparison to off-the-shelf options. The most important difference between the two is the quality of the prosthetic. Compared to off-the-shelf options, customized implants mimic the shape and function of the natural knee. These prosthetics have a higher success rate and lower risk of complications. Moreover, they are more effective than generic knee prostheses, so they can be more comfortable and less expensive for the patient.

The prosthesis is made from various materials. The majority of implants are composed of several components. The metal components are usually titanium or cobalt-chromium alloys. The metals are known to have good mechanical and chemical properties. However, some patients are allergic to metals and this may affect the type of implant they receive. A majority of implantable devices contain polyethylene to ensure that they glide smoothly within the mechanical joints. Unlike traditional knee implants, a cementless knee implant requires a bone graft.

Various materials are used to make knee replacement devices. The majority of implantable devices are made up of several components. These include titanium and cobalt-chromium based alloys. The metals are known to be durable and chemically inert. Rare metal allergies may also affect the type of implant chosen. Many implants are made of polyethylene, which is a soft material that glides within the mechanical joints and closely mimics the natural motion of a healthy knee.

The DePuy Sigma(r) Rotating Platform Knee is a type of implant that simulates the movement of the knee. Its manufacturer claims its mobile-bearing system reduces the stress on the knee and allows it to be more resilient to regular impact. Currently, this type of implant is in use in over twenty years. If your knee needs a knee replacement, it's time to look into this technology.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.