Surface treatment / deburring / cleaning

1 x SIGG sandblasting cabin with special coating only for VA parts 1 x SAPI sandblasting cabin...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Surface treatment / deburring / cleaning

1 x SIGG sandblasting cabin with special coating only for VA parts 1 x SAPI sandblasting cabin...

Vibratory grinding / barrel finishing

Solutions for the automatic deburring and polishing of precision parts With our partner, the fami...

Finishing processes for tablet tools

Tablet tools must be polished because the abrasive pressed powder reacts with and roughens their sur...

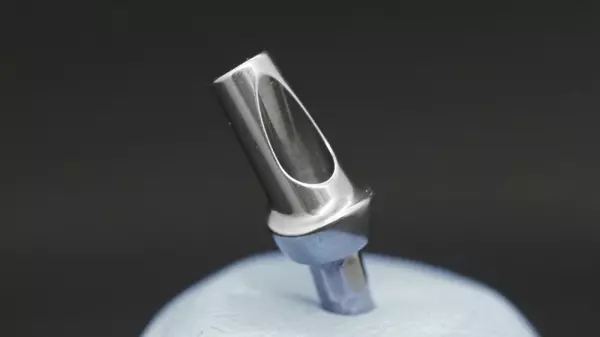

Finishing processes for implants

Knee joints, hip joints, dental implants, bone plates and bone screws Homogeneous, smooth implant...

Surface treatment - Tibia, femurshaft, pan...

The workpieces are clamped and processed with special brackets. Ra values down to 0.01 µm can...

Micro vibratory grinding machines

Micro vibratory grinding machines for deburring and polishing Micro vibratory grinding machines a...

OTEC can generate extremely flat surfaces through mass finishing, surfaces which are perfect for bea...

Post-processing of ready-to-install parts

We supply you with ready-to-install parts More and more manufacturing companies are reducing their v...

Contract manufacturing of precise turned...

Contract manufacturing of precise turned and milled parts for medical technology perame...

Small and micro parts are used particularly in medical technology. The surfaces that are achieved on...

Finishing processes for medical instruments...

Scissors, handles, drills, clamps, endoscopes and turned and milled parts Medical instruments and...

Vibratory grinding of medical components, vibratory grinding of medical components, vibratory grinding of medical materials, vibratory grinding of medical technology products, vibratory grinding of medical devices, vibratory grinding of implants, vibratory grinding of surgical instruments, centrifugal grinding of medical components, centrifugal grinding of medical components, centrifugal grinding of medical materials Medical technology products, centrifugal grinding of medical devices, centrifugal grinding of implants, centrifugal grinding of surgical instruments

Both types of grinding can be used for the processing of medical components. They are both effective in different settings and serve the same purpose. The advantages of both methods are that they are relatively inexpensive, and they can be customized to meet the requirements of a specific customer. The types of materials that can be ground include animal feeds, chemicals, coal, cocoa beans, coffee seeds, and cotton seeds. While some materials cannot be ground, they can be cryogenically ground using dry ice. In addition, "cyclone" collection chambers can be used for larger samples.

Both processes are effective for removing material from workpiece surfaces. The process uses a rotating disc and media. In the end, the workpiece surfaces are polished or deburred. The latter method is particularly beneficial for hard-to-reach components, such as gears. These two techniques require precise coordination and high levels of accuracy. To get started, choose one of the methods that best meet your specific needs.

Vibratory grinding and centrifugal spinning mills both use a high-speed rotation and two discs. The discs have a wide range of speeds. The process can be done with a high-speed rotary mill or a planetary ball mill. Both types of grinding machines can also be used for precision work. For example, a spindle milling machine is a high-speed machine that can handle parts of any size.

These machines are often more affordable than centrifugal grinding machines. Both types of finishing machines can be automated. Generally, round vibrators feature internal media and part separation. They are the benchmark for ease of use. A spindle mill is more expensive but can be used for smaller parts. In general, however, they are more productive. So, you can choose between centrifugal and vibratory methods.

While centrifugal grinding machines are both effective for many types of parts and applications, these machines are the most versatile and cost-effective option for small-scale production. Unlike other processes, they are easier to automate. For instance, vibratory equipments have internal media separation and can be a benchmark for convenience. The advantages of both methods make them equally useful in certain situations.

Centrifugal and vibratory machines can be used for the same applications. While both methods can produce the same results, they are a little more expensive than vibratory finishing. In contrast, the former is easier to operate and has higher capacities. It is also faster than centrifugal grinding, and its smaller size allows for higher production rates. If you need to grind very small parts, a centrifugal or rotary machine may be the better choice for you.

Both types of grinding machines are effective for small batches of materials. The latter is more affordable and is an ideal choice if you have limited space in your facility. A centrifugal machine is the best option for a small batch of material. The latter is used for larger-scale production. The two types of machines have different benefits. While vibratory finishes are better for small batches of material, tumbling mills can be used for larger quantities.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.