Lightweight X-ray suitcase for mobile use...

Leonardo DR mini III The gold standard for medical providers, disaster response and home care ser...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Lightweight X-ray suitcase for mobile use...

Leonardo DR mini III The gold standard for medical providers, disaster response and home care ser...

Compact desktop unit for digital X-ray

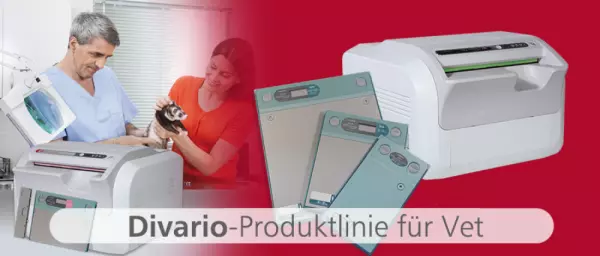

Digital X-ray with cassettes for standard X-ray examinations for vets The Divario CR-T2 is a...

Stationary and mobile X-ray for small animals

Amadeo V mini II Systems Space-saving full X-ray system for veterinary medicine with s...

DR retrofits (stationary and mobile) for...

Are you considering a digital alternative to your trusted stationary X-ray system? Is the time ripe...

Portable X-ray suitcase solutions for emergencies

Leonardo DR nano The wonderfully light, portable backpack X-ray system for emergencies Just s...

Stationary and mobile X-rays for human medicine

Amadeo Z motorised The compact U-arm X-ray system is motorised and designed for low ceiling heigh...

X-ray detection systems are designed to detect metals, plastics and other materials based on their density. Using these detectors is an easy and quick way to improve safety and production. Using these systems can save you time and money, as well as protect your products. Read on to learn more about these xray detection systems. And don't forget to check out our video on the benefits of these systems.

X-ray detection systems are ideal for many industrial applications. The materials being inspected determine the accuracy of the imaged objects. Since stainless steel is eight times denser than water, x-ray detection systems are effective in detecting even the tiniest piece of stainless. These systems can also detect ferrous and non-ferrous objects, including nails, screws, and jewelry. Depending on the type of product and application, they can detect items as small as onemm in size.

X-ray systems are used to detect items that have higher density than their products. They are also effective in detecting metals, glass, sandstone, quartz, shale, raw bones, and salt lumps. These detectors are extremely useful for identifying missing or broken products in packaging, unwanted air bubbles, overweight or broken products, and wrong position of individual components. With their versatility, x-rays are an excellent solution for any production environment.

X-ray detection systems should be able to detect bone and glass in glass. They should also be able to detect metal in metal cans. Using multiple x-ray detectors can help your manufacturing process run smoothly and ensure the safety of your products. Adding these systems to your production process will ensure you achieve high quality output while saving you time and money. So, don't delay and invest in a high-quality X-ray detection system today.

X-ray detection systems are important in a number of ways. The most common one is the use of a scintillator to convert x-rays to visible light. This scintillator can be used to identify different types of contaminants. Unlike a metal detector, a x-ray detector uses a scintillator. Then, it can be placed inside a glass box to detect hidden objects.

X-ray detectors are used to measure the properties of X-rays. Photographic plates and X-ray film are the most common type of X-ray detectors. Digitally-based systems are increasingly being used to improve OEE, or overall productivity. For instance, a single machine can produce thousands of products in a single day, but a few parts can be ruined. By using an exemplary metal detection system, you can ensure the safety of your product.

X-ray detection systems can make a huge difference in food safety. They are not just a convenient way to detect metals, but they also have the potential to prevent the occurrence of various diseases, such as cancer. In addition to detecting metals, they can also measure the lean value of a food by its chemical content and evaluate its weight. Most xray detectors are capable of inspecting up to 145 tons of meat per hour.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.