Food business operators are responsible for the safety of their products. This includes, among other things, complying with hygiene requirements during the production, processing, storage and distribution of food. The company must ensure that the rooms and materials are clean, the fruit is washed before cutting, the cooling temperature is maintained and the employees are trained regularly.

If the measures are not properly observed, it is possible for germs to multiply and consumers to become ill.

In Germany there is a nationwide monitoring plan that provides for official controls to be carried out on the basis of a risk analysis. As part of this monitoring program, 1135 companies nationwide that produce fruit salads were checked in 2021 . Defects were found in ¼ of the tested samples.

The shortcomings included, among other things, incorrect cooling: Pre-cut fruit should be stored at a maximum of 7°C. A lack of hygiene and deficiencies in the prescribed self-examinations were also identified. Pre-cut fruit salads are susceptible to microbial contamination and this risk can be minimized by following hygiene measures.

To ensure that your fruit salads do not become a health risk, Quant Qualitätssicherung GmbH supports you with advice on all aspects of food hygiene in your company. We help you to create and maintain your self-control concept, uncover deficiencies and train your employees.

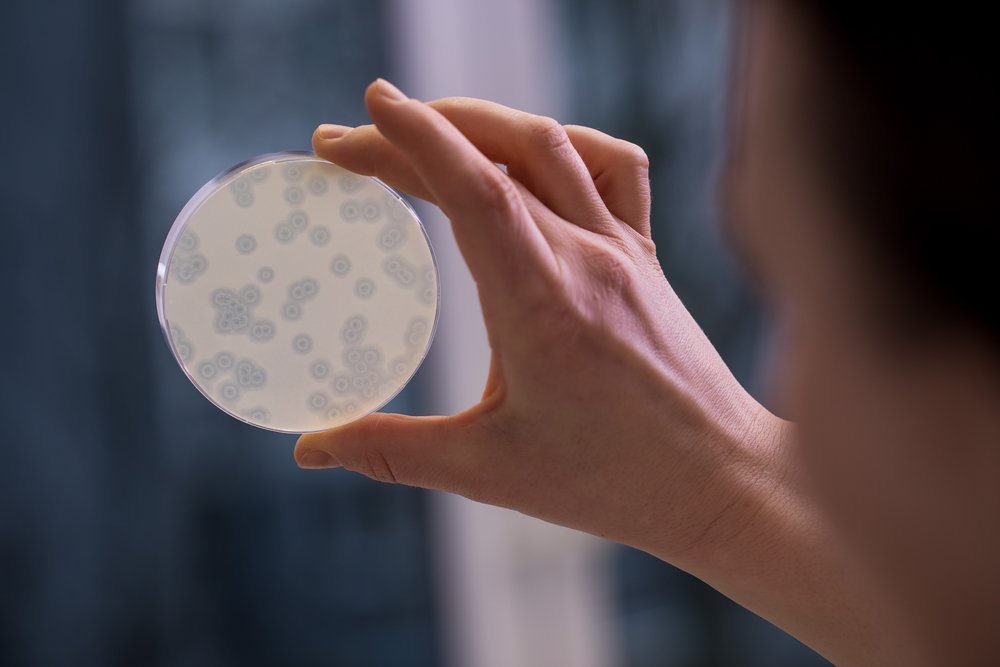

Our bilacon laboratory tests the microbiological quality of your products in order to detect possible pathogens and spoilage agents. Fruit salads contaminated with germs can sometimes lead to nausea, vomiting and diarrhea, so regular analyzes are important to protect the consumer: internally.

Torsten Michalski

Head of the Hygiene/QA department

Quant Quality Assurance Ltd

+49 174 156 08 25

torsten.michalski@tentamus.com

Tobias Stapper

Head of Microbiology

bilacon GmbH

tobias.stapper@tentamus.com

+49 30 206 038 370