NITINOL TUBES Nitinol Tubes Generation 1, 2 or 3 (HCF-High Cycle Fatigue) ASTM F2063 complia...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Healthcare & Medical assemblies

We are the reliable partner covering all areas from conception to (sterile) packaging of the finishe...

Product development, prototyping or the manufacture of technical series are different from the pro...

Standard instruments and specialist instruments...

The product portfolio covers our complete range with approximately 20,000 different standard instrum...

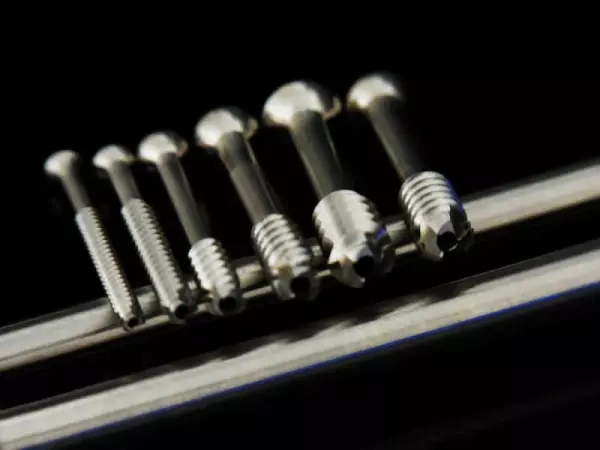

Raw materials for various surgical instruments

Since the company was founded in 1880, we have been manufacturing raw materials for various surgical...

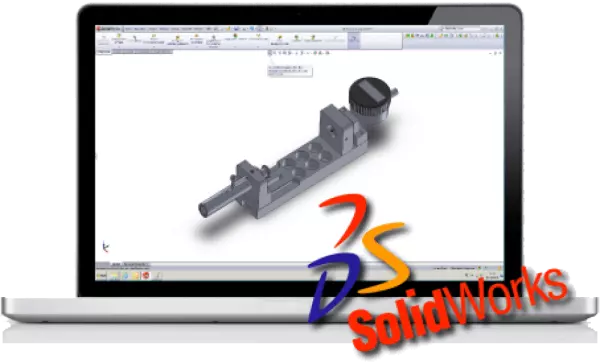

CAD construction / development of medical...

CAD construction / development of medical products CAD has supplanted the drawing board and many...

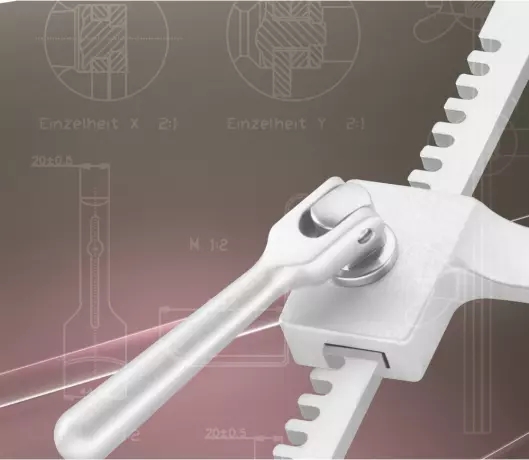

Our speciality: custom-made products You have a new idea or need an instrument solution for speci...

Orthopedic Products - Cutting Tools

The product range of cutting tools in the field of orthopedics includes: Bone drill Cu...

Contract manufacturing of precise turned...

Contract manufacturing of precise turned and milled parts for medical technology perame...

Décolletage & CNC turning / parts - contract...

Décolletage & turning - contract manufacturing for medical products In classic turning...

Orthopedic Products - Inserting Tools

The product range of cutting tools in the field of orthopedics includes: Phillips blades...

Round wires, flat wires, micro-profiles

ROUND WIRES WITH OXIDIZED OR OXID-FREE SURFACE NITINOL FLAT WIRES MICRO-PROFILES, REEL TO REEL...

thoracic surgery - High-quality VATS instruments,...

High-quality VATS thoracic instruments, suction, retractors, electrodes - Made by Dufner Instrumente...

Production / contract manufacturing of medical...

Production / contract manufacturing of medical products on behalf of customers Since our foundati...

Spine - Instruments & Implants

We develop, optimise and manufacture a variety of spinal implants and instruments (e.g. pedicle scre...

Milling technology / milled parts - contract...

Milling technology / milled parts - contract manufacturing for medical products Milling refers to...

Healthcare & Medical Advanced Consumables

We produce smart medical consumables with added value. Added value means optimized and expanded prod...

Orthopedic products - Navigating tools

Customized tools for navigating the drill holes and saw cuts

Up to date technology allows us to manufacture the most complex items even in low quantities. &nb...

Production of your OEM products - surgical...

Production of your OEM products - surgical instruments 100% Made in Germany OEM manufacturing...

The design process involved repeating the same steps multiple times, to produce fully functional and reproducible surgical sets. Each instrument was constructed using a 3D printer equipped with SLS Sinterstation HiQ technology. The process has numerous advantages, such as no increase in cost for increasing complexity, accelerated design-to-production times, and surgeon-specific modifications. However, the surgical instruments have only recently been commercialized. This project was the first of its kind in the United States.

During the development process, the researchers used simulated surgery sessions, in which the instruments were handled by participants in a non-surgical environment, and cadaveric inguinal hernia repairs. The results of the simulated surgeries helped them to make design changes that improved ergonomics and performance during the procedure. Table 1 shows the iterations that each instrument underwent. The design changes were driven by the feedback from attending surgeons and were influenced by their observations.

In order to develop a surgical instrument, the researchers used the SolidWorks CAD software. The surgical instrument designs were created with this program using DuraForm EX plastic powder. After the design process, the surgeons can easily view the 3D model by using a 3-D scanner. In addition, the cadaver models can be compared to a conventionally manufactured surgical instrument and are tested for their mechanical properties.

Hinged instruments also pose unique challenges. They require a delicate touch, excellent ergonomics, and exceptional structural strength. Three iterations later, the forceps were approved by a committee of surgeons and the resulting instrument was accepted by the group. The design is the result of more than two years of research and development, with more to come in the future. The process of 3D printing surgical instruments is currently being explored.

The manufacturing process is more advanced than before. A customized surgical instrument is manufactured according to the physician's specifications. These instruments are CE-marked and accredited to ISO 9001:2000. As a result, they are certified to meet the strict requirements of the Medical Devices Directive. Aside from being customized and adapted to the surgeon's preferences, they are also governed by a strict set of rules. A bespoke instrument can be made according to the physician's needs and can be used in a variety of applications.

The development process is a collaborative effort between surgeons and engineers. The team uses SLS technology to create the instruments, which is more advanced than traditional 2D versions. This type of fabrication process can also be used to create customized medical tools. Additionally, it can help patients and healthcare professionals save time and money. It is possible to print custom-designed surgical instruments for both humans and animals. For instance, 3D printed prosthetics can be more durable and can be more functional than traditional versions.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.