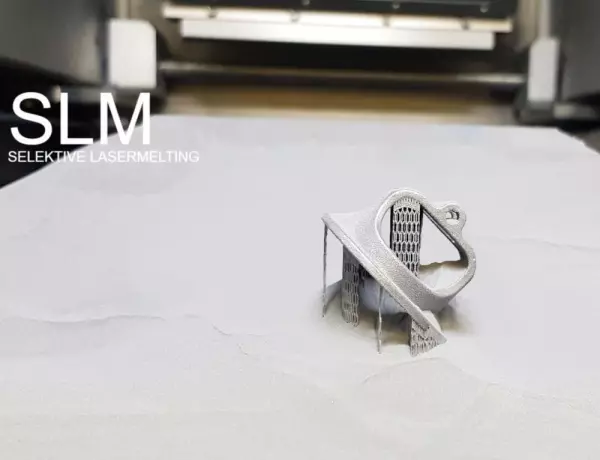

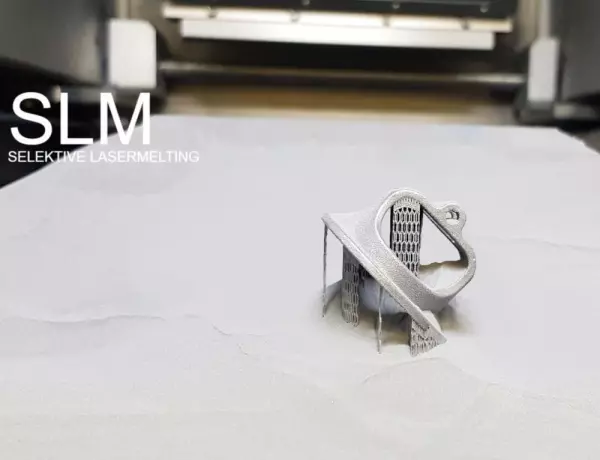

Selective laser melting (SLM), like laser sintering, is one of the methods of powder bed-based melti...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Selective laser melting (SLM), like laser sintering, is one of the methods of powder bed-based melti...

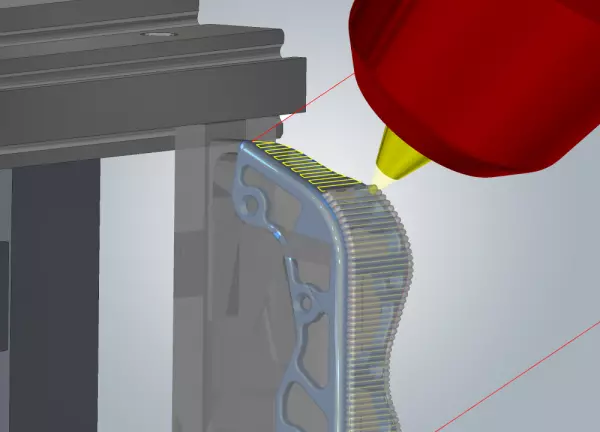

State-of-the-art technology and software allow us to translate the geometry of your product into a s...

News about COVID-19: Elbow door opener Corona viruses are transmitted as a droplet infection. The...

Additive manufacturing for medical technology

Additive manufacturing - only really perfect with CAD / CAM Additive manufacturing offers many ne...

What is 3D printing? It's a form of additive manufacturing, or creating three-dimensional objects from digital or CAD models. The process can create anything from complex mechanical parts to tiny toys. The process is simple to understand and can help you create unique objects for all of your creative needs. If you're interested in learning more about 3D printing, keep reading. In this article, we'll discuss some of the basics and the latest advancements in the field.

A recent study revealed that 3D printed tools can greatly improve the tooling process. In addition to speeding up the prototyping process, this technology can also improve the supply chain and storage processes. By using the latest in additive manufacturing, you can produce parts quickly and affordably. You can even maintain a digital inventory of parts in case you need replacement parts. And since you can print a high-resolution version of a part, it's easy to get one that matches your exact specifications.

With the help of 3D printing, medical professionals can design and manufacture custom insoles and orthoses. With this technology, they can avoid long wait times for customized tools that can lead to pain and discomfort. With better fit and comfort, these devices have been proven to improve the therapeutic outcome of patients and their recovery. This innovation is transforming the field of medicine. If you're interested in learning more about the new technologies and applications of 3D printing, keep reading!

FDA approvals: The FDA has recently approved the production of medical devices with 3D printing. This technology is rapidly advancing and will soon make its way into the hands of doctors worldwide. The FDA has several 3D printers at its facility and is testing them to determine their capabilities. This technology is a game changer for the medical field, allowing it to produce a wider range of products and improve patient care. In addition to reducing the cost and time required for clinical trials, 3D printing allows for more personalized designs and improved quality of life.

The speed of 3D printing makes it a valuable tool in the medical industry. It is unmatched in terms of production. This is crucial, as delays in the manufacturing process can lead to additional pain and discomfort for patients. The speed of 3D printing makes it incredibly easy to manufacture medical devices. It also allows doctors to make personalized surgical models of patient organs. It also helps them save lives by using advanced medical technology. Nevertheless, it is important to note that while this technology has many advantages, it is still a little bit more expensive than traditional methods.

While 3D printing is a powerful tool in the medical field, it can also pose a few challenges. First, 3D printing requires precision. A 3-D printed organ is likely to be highly accurate. Its high accuracy and ability to reproduce anatomical features can make it useful for the medical community. Furthermore, the process can be time consuming compared to conventional methods of creating anatomical models. The FDA can regulate the use of anatomical models, but it may not be worth it yet.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.