Safe deburring of titanium implants at Medartis

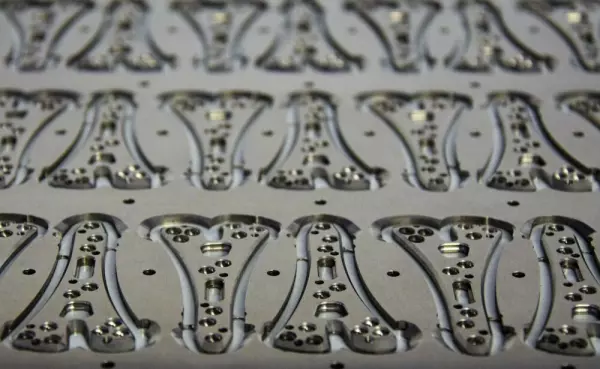

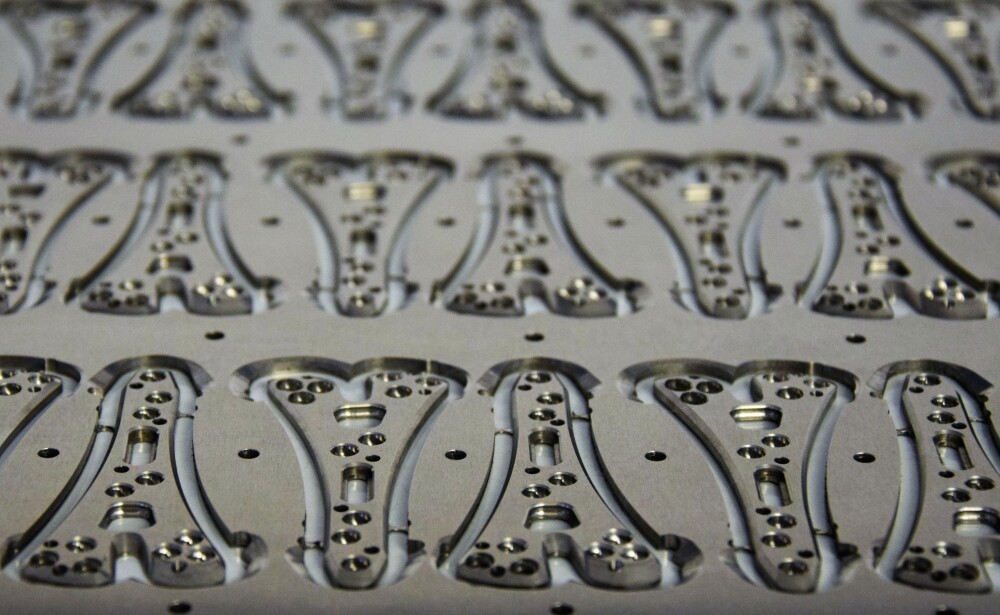

Medical industry: perfectly deburred bone plates in focus

René Gerber AG in an interview with Mr. Scheuble, Group Manager Process Engineering Plate, at Medartis AG. As a global innovation leader for implants, Medartis advances technologies and solutions for osteosynthesis in the areas of the extremities and facial skull in the medical industry and has had a Gerber brush polishing machine for deburring titanium blanks since 2008

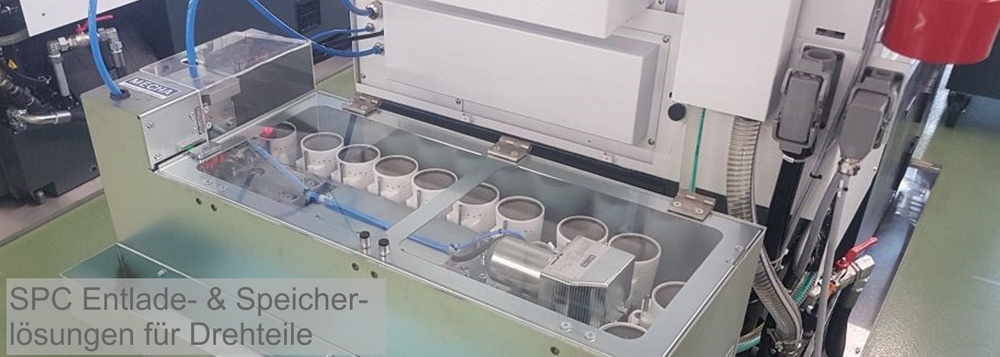

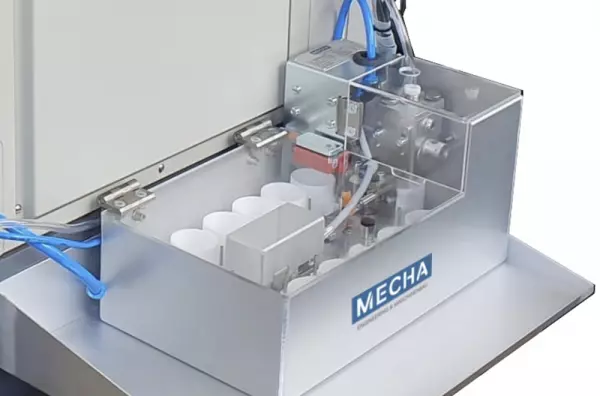

Medartis AG uses two brush polishing systems

There are numerous coincidences in life. The cooperation between Medartis AG, based in Basel, and René Gerber AG from the Bernese Seeland can also be ascribed to the pleasant coincidence.

When Medartis was looking for an economical method for edge rounding as part of a project in 2008, it became aware of Gerber at a trade fair. In conversation with Mr. Stefan Gerber, the focus was on the BP-MX as a solution-oriented brush polishing machine.

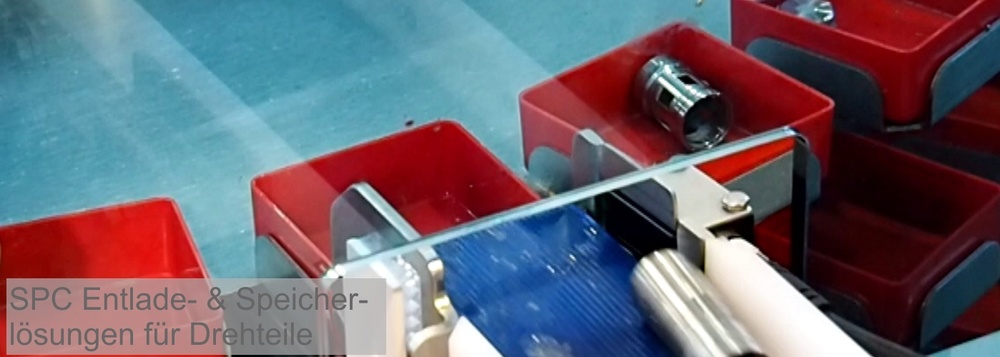

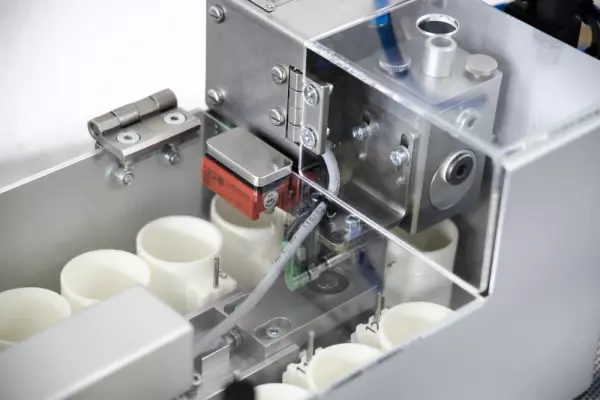

The brush polishing machine BP-MX brushes sharp edges and burrs / brushes precisely defined radii or contours on edges with a high degree of accuracy. At the same time the surface is polished

After the joint definition of the test setup and the subsequent tests at René Gerber AG, the system was expanded and built according to Medartis' needs. As Mr. Scheuble emphasizes, requests were dealt with professionally and individually and Medartis is very satisfied with the product and service from Gerber.

By purchasing the BP-MX system for deburring titanium blanks in a controlled manner on both sides, the manual deburring process was eliminated and employees can now be used for the relevant work steps. Medartis draws the success that it finds useful from this change.

Due to its high toughness, titanium places high demands on machinability. The residue-free deburring result was fortunately achieved in a short time. With the BP-MX the burrs can be completely removed up to the burr root. This gives Medartis a perfectly deburred bone plate, which is ready for the further process steps. The regular, fully automatic measurement and adjustment of the bristle length ensures the desired deburring result and process reliability.

By changing the following parameters it is possible to create different contours, shapes and surface roughness: material of the brush, brush density, brush speed, table speed, working pressure, working time and polishing agent

As Mr. Scheuble tells us, the BP-MX Medartis machine is satisfactory in several ways. With its footprint, the overall system is so small that it can be optimally integrated into the work area and the LEAN measures can also be implemented in a targeted manner.

The simplicity of operation and software is impressive. The employee responsible can activate another processing program or make adjustments with just a few input commands.

The loading of the BP-MX is at an optimal working height and can be carried out almost ideally. The integrated PLC control is user-friendly and leaves nothing to be desired.

"For us, the BP-MX is the ideal product with the right competent partner."

Mr. Scheuble, Medartis AG

The high efficiency and the evenness of the deburring result are the outstanding properties for Mr. Scheuble.

Medartis underlined the product satisfaction with the purchase of the second system in 2016. Thanks to the wide range of services and the solution approaches of René Gerber AG, the suitable process and the right machine for the high quality requirements could be found.

Mr. Scheuble, how would you describe the product / service in one sentence?

"In the end, success lies in a suitable process, the right partner, high product quality and satisfied employees."

Dear Mr. Scheuble, thank you very much for the interview and the insight into the cooperation between Medartis AG and René Gerber AG.

To the original article