A new unloading system automates Swiss type lathes

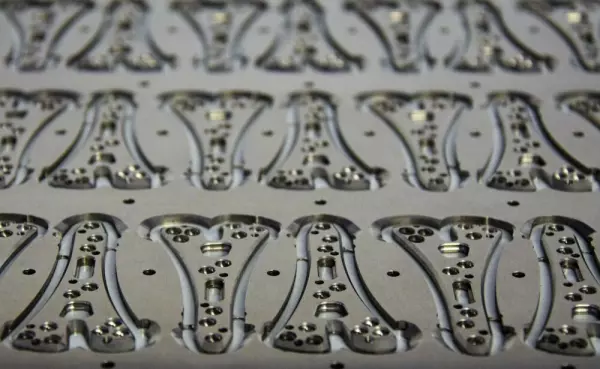

The Swiss MECHA AG develops unloading and storage systems for small and micro parts. At the beginning of 2021, MECHA will be presenting its newly designed Depotpallet handling system. Many precision parts in medical technology are now completely finished on CNC turning and milling centers. So that the parts are transported undamaged, safe and sorted, it is desirable to store them in pallets.

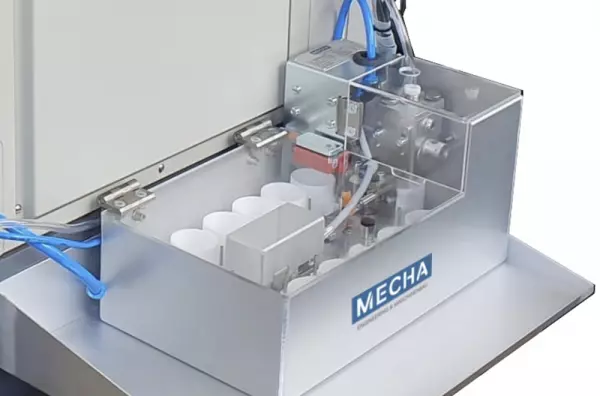

Efficient and space-saving

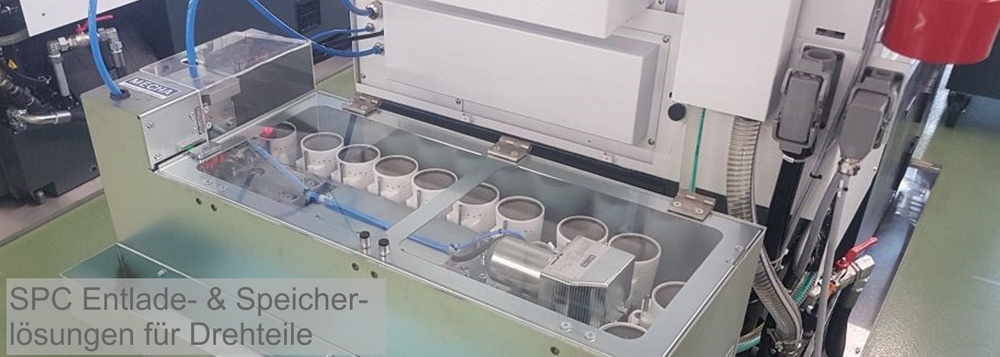

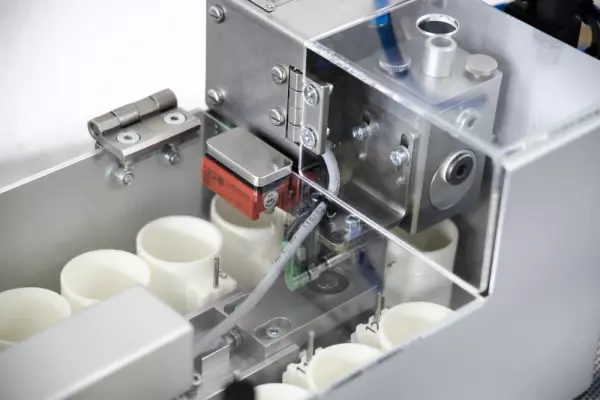

With the pallet storage system named DepotPallet P2V, MECHA supplies a space-saving handling device. It unloads small and micro-precision parts, as they are often manufactured in the medical and dental industry, by means of vacuum suction directly from the sub-spindle of the machine tool. A newly developed vacuum head places them in the pallet. At 642 x 455 millimeters, the floor space of the DepotPallet is significantly smaller than that of robot handling systems. The DepotPallet P2V has two pallets with a size of 210 x 230 millimeters. These are part-specific according to the diameter. With a diameter of four millimeters, the storage space is 300 parts per pallet. The total capacity of 600 parts is usually sufficient for several shifts. When the first pallet is full, the second, empty pallet is automatically reloaded.

Sustainability through reduction of rejects

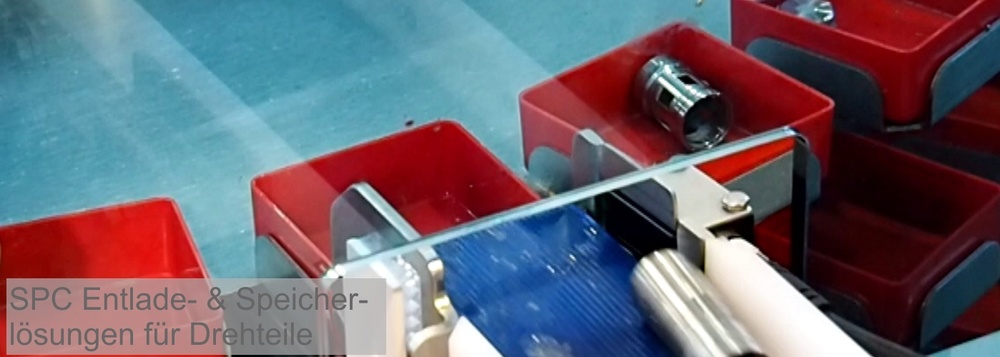

In medical technology there are many small and tiny parts that are manufactured with high precision. However, they are often lost on the way out of the machine. They stick, end up in the chip bucket or otherwise damage themselves. The vacuum suction system ensures that every part produced is placed on the pallet. Using the DepotPallet eliminates 99.9 percent loss of parts. This leads to fewer rejects, more parts produced and no damage to parts due to being transported out of the machine. The effort for the follow-up inspection of the parts can also be significantly reduced by using the DepotPallet.

Simple machine connection

The connection of the DepotPallet to a turning-milling machine is easy to realize. The mechanical interface is a vacuum hose, which can be up to 1.5 meters in length. This is attached to the ejection position of the counter spindle. From the electronic side, the DepotPallet only needs a signal for suction. Also provides the hangling device nor the signals to and fully available. A subsequent connection to existing machines is easy to implement in most cases.

Flexible use

The DepotPalett P2V pallet storage system is used for small and micro parts with a diameter of 1 to 9 mm. The DepotPallet can be quickly converted using a hose kit included with three hoses with different diameters. It can also be placed on a trolley and moved to and from the machine in a mobile manner.