The coating specialist Oerlikon Balzers is presenting "Surfaces for the future" at the AMB, the international exhibition for metalworking from September 13 to 17, 2022 in Stuttgart (Hall 1/Stand C62). New developments such as the carbon-based coating BALINIT MAYURA, BALIQ AN-TOS for taps, or BALINIT ALTINA for broaching tools as well as the diamond coatings of the BALDIA family are appearing to push the performance limits again. Indispensable trade fair topics are zude

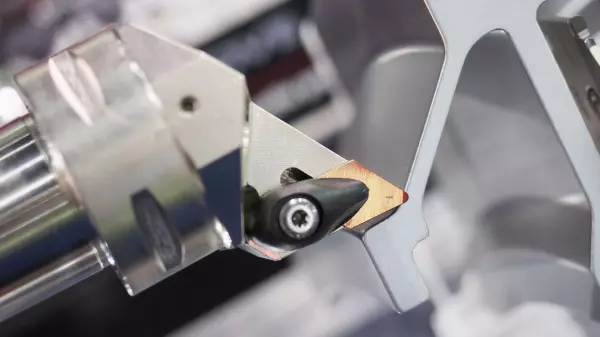

BALINIT MAYURA - Carbon-based coating for non-ferrous materials shows its colors

The latest, rainbow-colored ta-C coating is the next generation of carbon-based coatings for machining and forming non-ferrous materials. It is even harder and smoother than previous products, yet extremely thin and thus maintains the necessary sharpness of the cutting edges. With a minimal coefficient of friction, it reduces the formation of adhesions. It thus enables maximum precision and productivity in the machining of aluminum alloys with up to 12 percent silicon, copper and brass alloys and polymers.

BALIQ ANTOS – Tapping in stainless steel redefined

For Oerlikon Balzers, the future of tapping is called S3p (Scalable Pulsed Power Plasma). The advanced coating process creates hard and at the same time extremely smooth layers. The new development BALIQ ANTOS benefits from this: The extremely smooth AlCrN base layer ensures excellent hardness and wear resistance, the WC/C top layer has a very low coefficient of friction and the best dry lubrication properties.

This enables optimized running-in behavior when threading stainless steel, the torque remains extremely low and constant, without major fluctuation peaks. The homogeneous layer thickness distribution also leads to a very good representation of the cutting edge micro-geometry. Compared to previous coatings, BALIQ ANTOS achieves significantly longer service lives in tests and, above all, increases the process reliability that is crucial when tapping.

BALDIA – family of high-performance diamond coatings for all cases

The BALDIA portfolio offers solutions for every task related to the highly abrasive machining of graphite, ceramics or CFRP for markets such as mold making, dental, automotive or aerospace. The diamond coatings stand for extreme wear resistance and the highest standards of economy and quality. They enable the tightest tolerances. This applies in particular to the DC (Diameter Controlled) product line with BALDIA COMPACT DC and BALDIA COMPOSITE DC. These guarantee exact tool diameters and at the same time exact layer thicknesses.

BALINIT ALTINA – the new service combination for broaching tools

BALINIT ALTINA is not just a modern alternative to the common TiN and TiCN products for broaching tools. The AlTiN layer also has many advantages: on the one hand, significantly higher heat resistance with less sticking of chips and consequently higher component quality. With the new AlTiN coating solution from a combined service of decoating, edge preparation and coating, previously sharpened tools can now be fully coated. BALINIT ALTINA can be coated in large systems on tools with a total length of up to 3,000 mm, a coating length of 2,200 mm and a diameter of 500 mm.

Tool ID and myBalzers – unlocking potential with digital tool management and a service platform

With the digital solution ToolID, Oerlikon Balzers maps a holistic lifecycle management - from tool manufacture to use by the end user across all reconditioning cycles. The digital marking, identification and traceability of each tool opens the door to so-called chaotic production, to precise tool circulation planning through to the digital twin and enables enormous savings potential. According to the company, customers have already been able to save 30 percent of the work involved in incoming and outgoing goods. The optimized digital customer platform myBalzers offers a new level of digital services, from ordering and current status queries to complete document management. Trade fair visitors can test both applications at the Oerlikon stand (Hall 1, Stand C62) – hands-on digitalization.

For further questions please contact:

Oerlikon Balzers Coating Germany GmbH

Mrs. Anke Faber/Communication

At Ockenheim Graben 41

D-55411 Bingen

Phone: +49 (0) 6721 / 793 125

Fax: +49 (0) 6721 / 793 104

anke.faber@oerlikon.com

www.oerlikon.com/balzers/de

Press support Germany:

Thilo Horvatitsch text communication

office for press and public relations

Birkenweg 10

D-55268 Nieder-Olm

Phone +49 (0) 61 36 / 468 90 20

Fax +49 (0) 61 36 / 468 62 34

thilo@horvatitsch.de

www.horvatitsch.de