Oerlikon Balzers, an Oerlikon technology brand and global leader in high-performance thin-film PVD coatings, is presenting its latest surface solutions at FAKUMA, the international trade fair for industrial plastics processing, taking place from October 17th to 21st in Friedrichshafen. The surface technologies offer optimal protection against abrasive wear and corrosion in the plastics processing industry and are in line with the Nac

In injection molding and extrusion, the surface finish of the molding tools plays a central role in both surface quality and productivity and efficiency during the manufacturing process. With planned maintenance and the avoidance of unexpected failures, high-quality surface solutions can save significant production costs. In combination with hot runner systems from the sister brand Oerlikon HRSflow, processes in plastics processing can be further optimized.

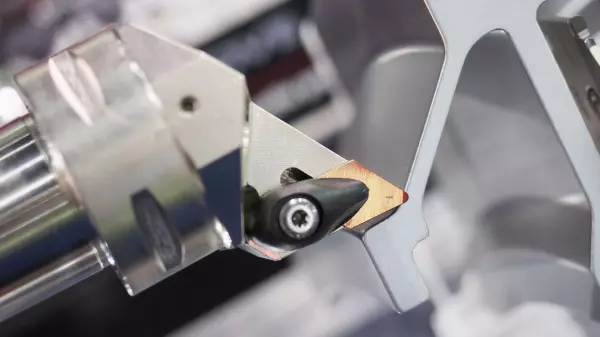

BALINIT MAYURA – High-precision coating of non-ferrous tools for injection molding

The carbon-based layer BALINIT® MAYURA immediately catches the eye with its distinctive bright rainbow colors and shows its true value when injection molding with delicate tools made of non-ferrous metals and tool steels with a tempering temperature below 200 °C. Due to its exceptional hardness (>65 GPa) and smoothness, it minimizes material adhesions and is resistant to chipping. At the same time, the sharpness of the separating edges is retained thanks to the extremely thin layer. BALINIT MAYURA has a low process temperature but high thermal and chemical stability and can withstand application temperatures of up to 500 °C, which are usually limited to 350 °C for carbon coatings. It is suitable for all applications in which abrasion and adhesions occur in combination. Manufacturers benefit from longer tool life and higher productivity in the manufacturing process.

BALINIT MOLDENA – injection molding of recyclable plastics

The PVD layer BALINIT CROMA PLUS from Oerlikon Balzers protects molds from abrasive wear, corrosion and sticking and has proven itself over many years in the injection molding and extrusion of numerous plastics.

Its successor, BALINIT® MOLDENA, is the ideal protective layer for injection molding with aggressive glass fibers in plastics, which are increasingly used for weight-reducing components in order to save raw materials and further reduce emissions. It optimizes flow behavior, increases corrosion resistance, makes demoulding easier and significantly reduces abrasive wear and the formation of deposits.

BALINIT MOLDENA is very hard and only a few micrometers thin. The layer is also designed for fully recycled materials to return to the circular economy, or those with high levels of flame retardancy. BALINIT MOLDENA has already proven itself in injection molding projects for customers, with the reject rate being reduced to zero and the number of injections being significantly increased while maintaining consistently high product quality.

BALITHERM PRIMEFORM – heat treatment for molds with shiny surfaces

Highly polished surfaces of plastic injection molds are very sensitive. Treatment with BALITHERM® PRIMEFORM improves demoulding, optimizes process reliability and increases component quality. Even heavily used areas can be protected from scratches, environmental influences and improper handling. BALITHERM PRIMEFORM increases the surface hardness of injection molds up to 1400 HV, makes them significantly more robust and reduces adhesion, chipping and brittleness on edges. It is ideal for plastic injection molds in the automotive, furniture, packaging and medical industries. The diffusion process can increase efficiency by up to 60%.

Polishing and coating service from Oerlikon Balzers

Oerlikon Balzers offers its customers a complete service, including polishing and coating, that is optimally tailored to the mold. Depending on the requirements of the application, the highly qualified specialist staff carries out line polishing with a specified grain size or high-gloss polishing, even on site at the customer's premises if requested.

Optimized processes in Oerlikon’s industrial plastics processing

In industrial plastics processing, customers benefit from an optimally coordinated manufacturing process with the latest Oerlikon HRSflow hot runner systems and Oerlikon Balzers surface solutions. The experts from Oerlikon will advise visitors in Hall 1, Stand A1-1215/1216 about the various solution combinations of hot runner systems, tool coatings and heat treatments.