Balzers, Liechtenstein / Hanover, Germany, July 18, 2023 – On the exhibition stage at EMO 2023 from September 18 to 23 in Hanover, Oerlikon Balzers, one of the world's leading technology brands of the Oerlikon Group, is putting its current high-tech surface solutions in the spotlight. The S3p coating BALIQ TISINOS PRO for hard machining up to 70 HRC will be presented for the first time, further highlights are the carbon layer BALINIT MAYURA, the diamond coatings of the BALDIA family so

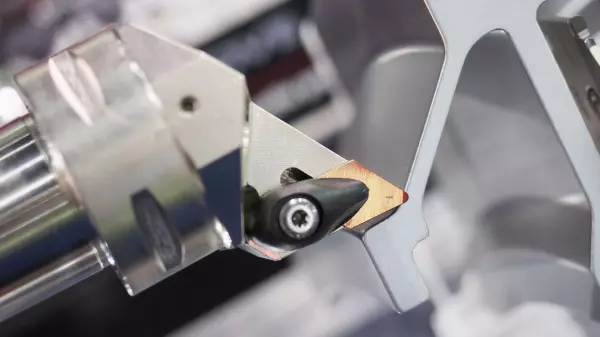

The new layer BALIQ TISINOS PRO from Oerlikon Balzers clearly shows how nuances sometimes become class differences. BALIQ layers are based on the S3p (Scalable Pulsed Power Plasma) coating technology. It combines the advantages of the arc evaporation (Arc) and magnetron sputtering processes and thus pushes the performance limits of conventional HiPIMS coatings. On this basis, it was possible to further refine the microstructure and layer smoothness and thus achieve even better wear resistance of BALIQ TISINOS PRO. When machining high-temperature alloys as well as stainless and hardened steels up to a hardness of 70 HRC, the AlTiSiN coating withstands high thermal loads and ensures even more stable processes. In tests with end mills, there was an average increase in service life of up to 50 percent compared to the previous coating, with higher production quality, especially in micro-machining.

Carbon and diamond coatings for non-ferrous metals, lightweight construction and moreBALINIT MAYURA is not only attracting increasing attention because of its rainbow colour. The thin and extremely hard ta-C layer for processing non-ferrous materials such as aluminium, copper and brass alloys as well as polymers minimizes material adhesions on the tool and at the same time preserves extremely sharp cutting edges. High precision, longer service life and thus increased productivity are increasingly leading tool manufacturers and end users to switch to the BALINIT MAYURA, which was presented in 2022.

In addition to mold making, the BALDIA family from Oerlikon Balzers also serves innovative markets such as dental, automotive and aerospace. The CVD diamond coatings master the highly abrasive machining of graphite, ceramics or CFRP/GFRP materials and thus support sustainable manufacturing solutions in electromobility and lightweight construction. For example, BALDIA COMPOSITE DC achieved a service life that was more than three times longer when drilling in CFRP in aircraft construction, while tool costs fell by more than half.

Digitization: tool management, customer platform and system monitoringUsed correctly, even small bits and bytes make great things possible: Tool ID opens the door to holistic lifecycle management from tool manufacture to use by the user, including reconditioning. The basis of this tool management system is the digital marking for the identification and traceability of each tool.

myBalzers also provides digital services at the highest level: Visitors to the exhibition stand can test what the customer platform has to offer, from paperless ordering and current status queries to complete document management.

There is also hands-on software for those interested in coating systems: A brand new and user-friendly HMI (Human Machine Interface) solution for METAPLAS.DOMINO systems from Oerlikon will be demonstrated, which brings with it highly efficient real-time monitoring and visualization of the system. A cloud-based IIoT (Industrial Internet of Things) service for end-to-end data networking of Oerlikon coating systems is also making progress in this direction, offering enormous potential for increasing productivity.

From metal powder and thermal spraying to additive manufacturingOerlikon Metco stands for expertise in all aspects of thermal spraying and as a supplier of special metal powders for additive manufacturing, which in turn drives Oerlikon AM forward as an innovator and solution provider.

This allows trade fair visitors to experience the comprehensive portfolio of surface solutions from Oerlikon.

To the original article