Anyone who enables the machining of high-strength materials with ultra-hard CBN cutting materials is playing in the champions league of machining. BSW Zerspanungswerkzeuge wants to set benchmarks here – with the coating of indexable inserts with BALIQ TISINOS from Oerlikon Balzers.

Cubic boron nitride or CBN is almost as hard as diamond. It is used, for example, in the automotive and aviation industries for machining high-strength materials. “Where CBN is used, there is often no alternative. That's why we want to offer our customers the most innovative product at the highest level of quality and set a benchmark in the market," says Oliver Roski, Head of Technical Sales at BSW Zerspanungswerkzeuge GmbH. The company from Saarwellingen generates around half of its sales with CBN products - primarily with indexable inserts. "Together with our customers, we develop individual special solutions for the respective application," says Roski.

BSW has already used BALINIT coatings from Oerlikon Balzers for its tool solutions. It was an important goal to make wear visible in good time, because the uniform gray color of the indexable inserts makes it difficult to see wear. This can lead to a loss of quality during use or to premature disposal of plates that are still functional. The gold-colored coatings with BALINIT ALCRONA PRO Gold or BALINIT A, on the other hand, make wear and tear immediately visible.

Zero failure, perfect quality

CBN cutting materials are temperature-stable up to 1000 °C and are therefore ideally suited for dry machining. However, these tools are also subject to increasing demands. A BSW customer wanted a coating on his indexable inserts that made wear visible and at the same time led to an increase in performance.

However, coating CBN is not easy. Different tensions between the substrate and the coating can easily lead to stress cracks and the coating can flake off. BSW found the right development partner for this problem in Oerlikon Balzers. "One of our most important specifications was process reliability: zero failure and perfect quality, because the panels are very expensive. Its value is many times that of the coating,” explains Felek Ciftci, Head of Purchasing at BSW.

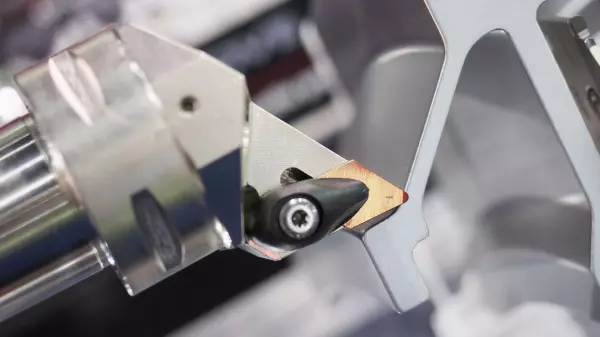

Working closely together, the BSW experts and Metin Cetin from Oerlikon Balzers developed a solution. The choice fell on BALIQ TISINOS. This AlTiSiN layer is based on Oerlikon Balzers' S3p technology (Scalable Pulsed Power Plasma) and, at 1000°C, has the same operating temperature as CBN. It achieves excellent oxidation resistance, density and homogeneity, is extremely smooth and enables exact cutting edge mapping.

Partner service fits

The partner service from Oerlikon Balzers is also particularly valued at BSW. In addition to technical advice, this also includes a delivery and collection service as well as processing true to the position on special mounting equipment including packaging, specially developed for the BSW indexable inserts. “Our panels are assigned to a specific customer or order. So it was important for us that our coating partner can fulfill this charging,” explains Felek Ciftci. This full service is made possible not least by the processes in the Oerlikon competence center for S3p coatings in Bielefeld, which also specializes in CBN.

With the use of the copper-colored layer BALIQ TISINOS, BSW can kill two birds with one stone: Wear is detected and service life is increased. "Depending on the application, this can be up to 50 percent," says Oliver Roski. "If a coating with BALIQ TISINOS makes sense for the respective customer and application, we can now offer him the perfect solution. And if not, we continue to enable pure wear detection.”

To the original article