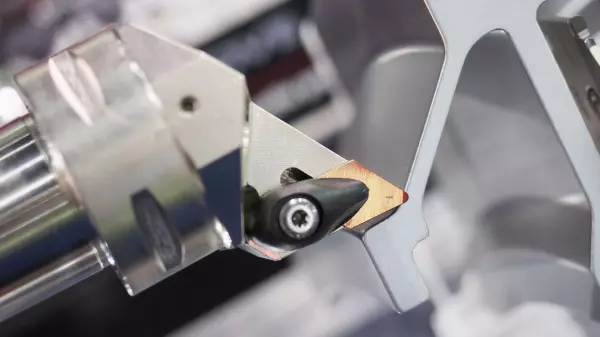

Balzers, Liechtenstein, July 4, 2023 - When processing hardened steel, stainless steel or high-temperature alloys, tools are subjected to high thermal loads. With BALIQ TISINOS PRO, Oerlikon Balzers, one of Oerlikon's leading global technology brands for high-tech surface solutions, is setting a new standard. The PVD coating was specially developed for these materials. It reduces tool stress and improves wear resistance when hard machining steel

An example of the technological leadership and competence of Oerlikon Balzers is the S3p coating technology (Scalable Pulsed Power Plasma). It combines the advantages of arc evaporation (arc) and magnetron sputtering processes, thereby pushing the performance limits of conventional HiPIMS coatings. The advantages of S3p are longer high-current pulses and a high current density, which cause strong ionization of the layer. The BALIQ layers developed on this basis are characterized by their extraordinary smoothness, homogeneous layer distribution, extreme density and hardness, very good adhesion to the substrate and high wear resistance.

Machining steels up to 70 HRC is common in many industries today. With BALIQ TISINOS PRO, customers benefit from a PVD coating with a further refined microstructure that offers even greater resilience and wear resistance. One of their unique properties is the excellent smoothness that protects all shapes and cutting edges evenly, which is particularly crucial for micro-machining tools. This allows for even chip evacuation, minimizing scrap and avoiding expensive and time-consuming mechanical rework.

The AlTiSiN-based coating withstands high thermal loads and protects the carbide substrate from thermal corrosion and oxidation. Thanks to the homogeneous layer thickness distribution, BALIQ TISINOS PRO ensures sharp cutting edges, which leads to lower cutting forces and higher process stability at the same time.

When tested with a customer's ball end mill, BALIQ TISINOS PRO far exceeded the service life of its predecessor. As a result, BALIQ TISINOS PRO offers significantly longer service lives, higher process reliability and thus greater efficiency. Thanks to the superior performance of BALIQ TISINOS PRO, users can also benefit from higher cutting speeds in order to shorten processing times and thus reduce overall production costs.

Overall, the robust performance of BALIQ TISINOS PRO extends the service life of an end mill by up to 50% on average compared to the previous coating. This reduces tool changes and the associated downtimes, which leads to lower overall energy consumption. In addition, remanufacturing end mills extends their service life and reduces the need for new tools by around 30%, making Oerlikon a sustainable and resource-efficient supplier in the metalworking industry.

dr Andreas Reiter, Head of Product Line Tools, explains: "Thanks to the further refined microstructure, we have further improved the properties of BALIQ TISINOS PRO. The coating ensures an even more stable and reliable machining process, which leads to high-quality components, especially in micro-machining, and thus to fewer tool changes. In addition, customers can have their tools recoated with BALIQ TISINOS PRO. This not only saves tool costs, but also contributes to sustainability by saving valuable raw materials.»

BALIQ TISINOS PRO will be presented live for the first time at EMO 2023, which will take place from September 18th to 23rd, 2023 in Hanover.

To the original article