Balzers, Liechtenstein, September 13, 2022 – Oerlikon Balzers, one of Oerlikon's leading global technology brands for high-quality surface solutions, presents BALINIT MAYURA, a new carbon-based coating for machining and forming non-ferrous materials. With BALINIT MAYURA, manufacturers and end users benefit from longer tool life and higher productivity in the manufacturing process.

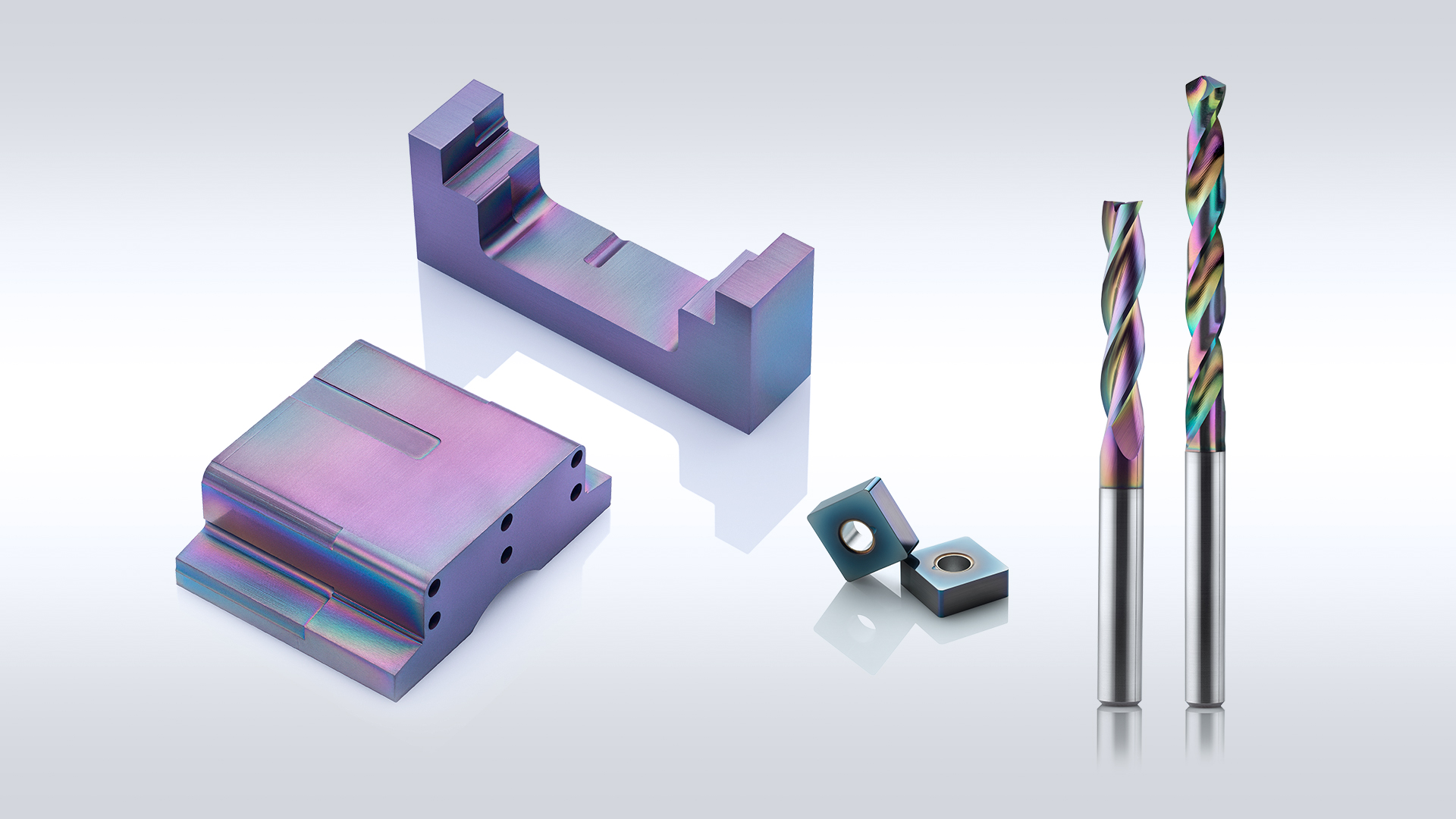

BALINIT MAYURA attracts attention with its unmistakable brilliant rainbow colors. However, it shows its real value in the demanding machining of non-ferrous materials, such as aluminum alloys with up to 12 percent silicon, copper alloys such as phosphor bronze or brass and polymers.

Aluminum alloys are used in particular, but not exclusively, in the automotive and aviation sectors. Due to their lower weight compared to conventional materials, they make a significant contribution to complying with the strict specifications with regard to CO2 or NOx emissions. With the growing importance of e-mobility, the processing of copper alloys is also becoming increasingly important. "With BALINIT MAYURA, we offer our customers a solution that is tailored precisely to these demanding materials, the process and the application, with which they benefit from optimum performance at lower production costs," says Dr. Andreas Reiter, Head of Product Line Tools at Oerlikon.

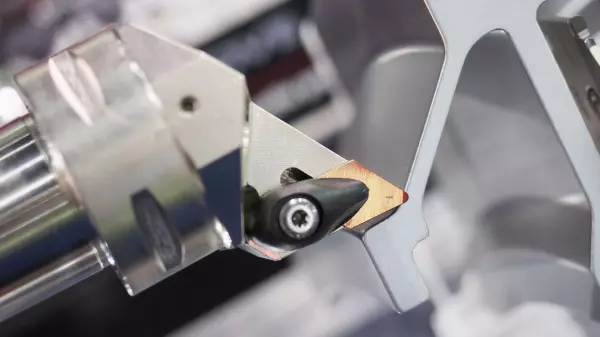

BALINIT MAYURA is harder and smoother than comparable layers, extremely thin and heat-resistant. Due to these properties, it is particularly suitable for the demanding processing of non-ferrous materials. The greater hardness and exceptional smoothness effectively reduce material build-up, which minimizes built-up edges and facilitates chip flow. The reduced coefficient of friction due to low roughness allows low torques. When punching and forming aluminum, for example, the tendency to adhere, the formation of burrs and spangles is reduced.

The extremely thin layer keeps the sharpness of the cutting edges longer. In this way, manufacturers and end users benefit from high precision, longer service lives and an overall more stable production process. Since tools with BALINIT MAYURA can be recoated several times, the new carbon layer also helps to conserve resources.

Visit the BALINIT MAYURA website for more information.

To the original article