Bingen, April 13, 2022 - Longer service life, longer maintenance intervals, higher yield - these are the results achieved by surface treatments of tools for plastics processing with BALINIT® CROMA PLUS or BALITHERM® PRIMEFORM. Oerlikon Balzers will be presenting these at KUTENO (Kunststofftechnik Nord) 2022, the regional supplier fair for the plastics processing industry, from May 10th to 12th in Rheda-Wiedenbrück (Hall 1, Stand D16). The coating specialist also focuses on d

BALINIT® CROMA PLUS is an exception not only because of its characteristic rainbow colour. Large tools up to four and a half meters in length can be protected with the CrN-based multi-layer coating including an oxide cover layer. In film and blown film extrusion, the extremely hard and smooth layer has already achieved a wide range of advantages in customer use, from protection against abrasion and scratches to less deposit formation and longer cleaning cycles to improved flow behavior of the melt. In profile extrusion and granulate production, the surface quality of the components was improved by coating calibration bars and less wear and tear when using perforated plates. With its high oxidation resistance and excellent layer adhesion, BALINIT® CROMA PLUS scores particularly well in the case of corrosion, abrasion and sticking, for example in rubber compounds.

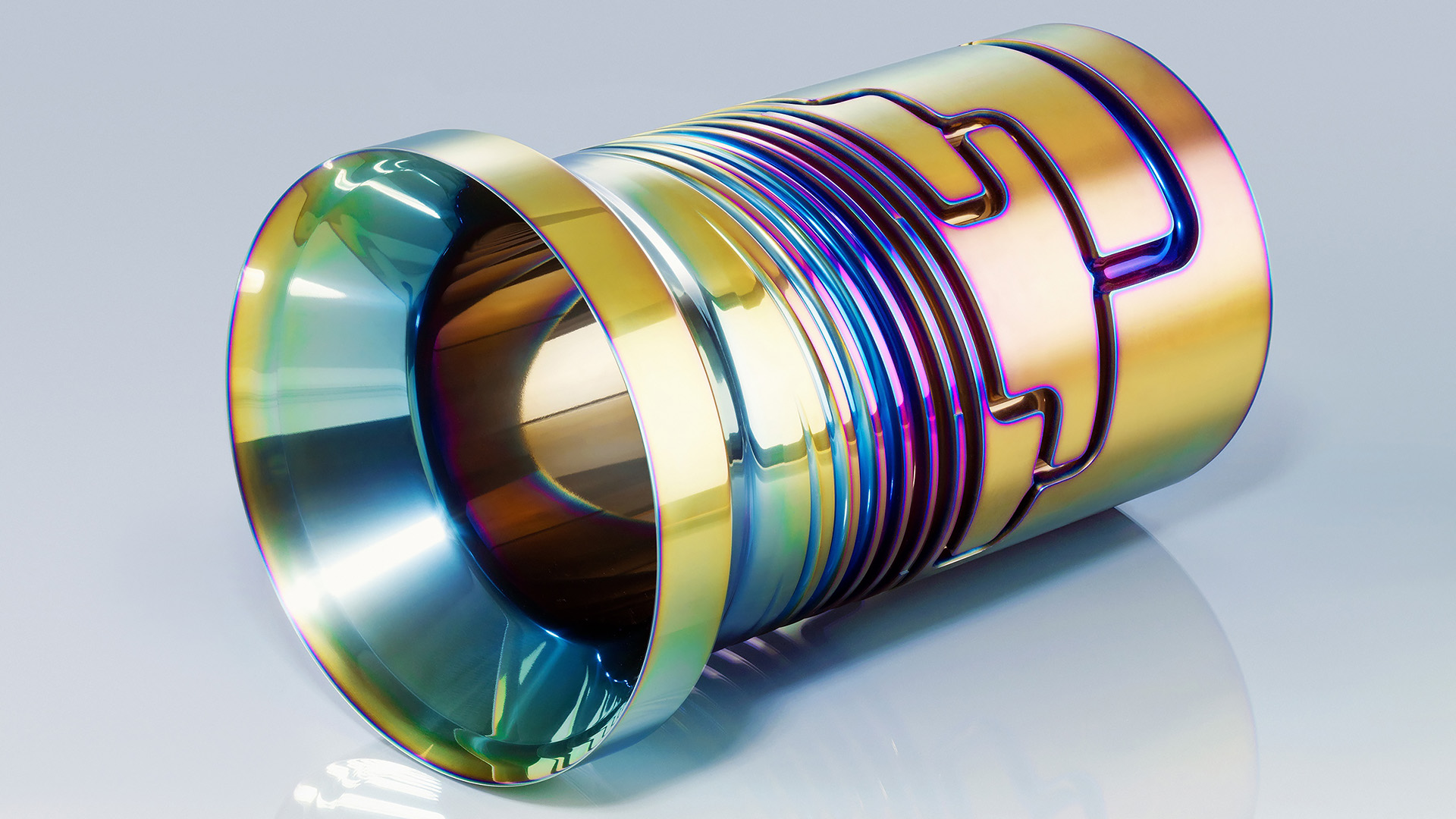

The plasma treatment of injection molds with BALITHERM® PRIMEFORM kills several birds with one stone: The diffusion process increases the surface hardness to 1,400 HV and penetrates directly into the base material without layer deposition on the surface. This means that the tool can easily be subsequently polished to a high gloss, blasted to a high gloss, repaired or welded if scratches occur. Scarring or laser structures can also be applied before or after the treatment. Further advantages are better demoulding, even with deep rib geometries, and easy, quick cleaning of the mold. The bottom line is that this significantly reduces maintenance costs and downtimes.

Complete service for high-gloss polishes

The complete service consisting of pre-polishing, surface treatment/coating and finishing is particularly suitable for high-gloss polished injection molding tools and manufacturers of automobiles, white goods, electronic devices and products for the medical and pharmaceutical industry who rely on premium optics. It begins with high-gloss polishes with low roughness values (Ra = 0.06 m / Rz < 0.2) with maximum dimensional accuracy (+/-0.003 mm). For even better surface protection, treatment with BALITHERM® PRIMEFORM and an additional PVD coating can be added. The result is flawless, reflective surfaces of tools and plastic items, protection against scratches and better cycle times. In return, Oerlikon Balzers promises close project support, high delivery reliability and on-site polishing at the customer's.