Bingen, December 1st, 2021 - With increased performance, the multicolored high-performance coatings of the BALIQ UNIQUE family from Oerlikon Balzers can be used for shank and micro tools as well as for special series and special indexable inserts. In addition to the color differentiation as a marketing advantage, customers discover another benefit: more production reliability through unmistakable tool colors.

Tool manufacturers and dealers, but also producers from medical technology or other industries rely on the iridescent layer. This is because they can use it to assign specific colors to applications, product types or groups – a differentiation option that the market had been looking for for a long time. This was made possible on the basis of the advanced coating technology S3p (Scalable Pulsed Power Plasma) from Oerlikon Balzers. This not only creates extremely smooth coatings with outstanding wear protection properties, it also enables the realization of a unique spectrum of currently 29 possible color tones.

Since BALIQ UNIQUE has been further developed with a view to new markets, the coating family can be used not only for large series but also for limited special series and for special indexable inserts with a bore. There are tangible advantages for users. Different tool specifications such as geometries, radii, step diameters or angles can also be clearly identified with colors. A step length of 3 or 4 millimeters can hardly be distinguished at a glance. And a mistake in the stress of operation can have fatal consequences: rejection of high-quality parts, more costs, effort, time and trouble with customers. "On the other hand, the color coding creates operational and cost security right through to the finished component," says Rico Fritzsche, Segment Manager Machining at Oerlikon Balzers.

Individual construction kitAll users can choose from an individual modular system with several functional layers for BALIQ UNIQUE. The AlTiN-based all-round layer BALIQ ALTINOS, for example, is particularly suitable for milling and drilling, for machining stainless steel and for indexable inserts. The AlTiSiN-based high-performance layer BALIQ TISINOS has its strengths in particular in the drilling and milling of high-temperature-resistant alloys and hard machining up to 70 HRC.

The performance of the further developed layer was tested at the Institute for Production Technology (IPT), a long-term partner before Oerlikon Balzers at the HAW Hamburg. In a comparison test with the benchmark product BALINIT ALNOVA, BALIQ UNIQUE achieved longer service lives with the BALIQ ALTINOS functional coating when milling stainless steel (42CrMo4). In the drilling test with the functional layer BALIQ TISINOS, BALIQ UNIQUE reduced the tendency to stick in the flute, the guide chamfers looked almost untouched. This means less risk of chip jamming and drill breakage.

All in all, the expanded options are well received by customers: "We can now bundle the color differentiation and the increased performance potential of BALIQ UNIQUE," says Dirk Kaffenberger, Sales Manager at Precision Tools Schmidt. The tool manufacturer from Zella-Mehlis uses the product with the functional layer BALIQ TISINOS in the color green on TRIPLEX-Q NATURE GREEN HPC milling cutters for the highly heat-resistant machining of titanium and Inconel.

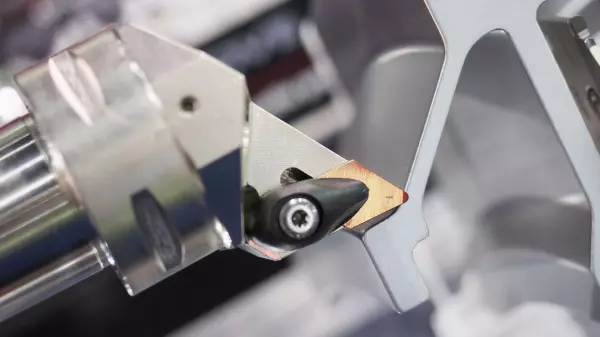

Figure 1 a/b

With increased performance and a range of currently 29 possible colors, BALIQ UNIQUE serves a large range of tools. Photo: Oerlikon Balzers

Figure 2a/b

In laboratory tests, BALIQ UNIQUE scored well when milling stainless steel (left) and when drilling (right). Photo: Oerlikon Balzers

For further questions please contact:

Oerlikon Balzers Coating Germany GmbH

Mrs. Anke Faber/Communication

At Ockenheim Graben 41

D-55411 Bingen

Phone: +49 (0) 6721 / 793 125

Fax: +49 (0) 6721 / 793 104

anke.faber@oerlikon.com

www.oerlikon.com/balzers/de

Press support Germany:

Thilo Horvatitsch text communication

office for press and public relations

Birkenweg 10

D-55268 Nieder-Olm

Phone +49 (0) 61 36 / 468 90 20

Fax +49 (0) 61 36 / 468 62 34

thilo@horvatitsch.de

www.horvatitsch.de