Balzers, Liechtenstein, December 16, 2021 – Oerlikon Balzers, a leading provider of surface solutions for the metal and plastics processing industry, has delivered coating systems and solutions for the metallization of plastic parts to the BMW Group plant in Landshut. The ePD technology developed by Oerlikon Balzers enables innovative functions and designs and complies with REACH environmental regulations. In September, the BMW Group won the Grand Award for innovative art

The Oerlikon Group has anchored sustainability and environmental protection as key elements in its corporate strategy. To implement this, Oerlikon Balzers, as a competence brand, develops coating solutions and systems for its customers that help to use resources sparingly and significantly reduce CO2 emissions. Innovative functions and design concepts play an important role in the development of future automobile generations. The BMW Group uses the sustainable ePD technology from Oerlikon Balzers for its new all-electric BMW iX.

ePD: Ecologically clean, REACH-compliant process with low energy consumption

ePD™ (embedded PVD for design parts) is an environmentally friendly and future-oriented coating process that can be used wherever high-quality metal surfaces are required on plastic parts with smart functions. The three-layer structure made of UV coatings and an embedded PVD layer is considered groundbreaking for new design concepts for plastic components for automobiles with purely electric or hybrid drives. The combination with other technologies such as laser marking, digital, screen or pad printing opens up even more possibilities for designers and engineers.

Due to its low energy requirements and the avoidance of hazardous waste, the ePD™ process is environmentally friendly and cost-effective, which is particularly appreciated by companies that operate sustainably. In addition, the European Union has also launched the so-called REACH standard, which intends to initially restrict the use of harmful substances such as cobalt salts, boric acid and nickel and later to no longer permit them at all.

New innovative functions for the next automobile generation

With the INUBIA, the BMW Group can offer its customers metalized components of the highest quality. Interactive communication between vehicles will play a much greater role in autonomous driving, for which Oerlikon Balzers' ePD technology already offers solutions that are also visually appealing. One example of this is radar-transparent layers for driver assistance systems: For example, a radar sensor for measuring the distance to the vehicle in front can be easily installed behind a radiator grille that has been finished with an ePD layer. Due to the special manufacturing technology, capacitive or translucent components can also be manufactured whose functionality remains invisible and thus blends harmoniously into the design concept of modern vehicles. Because the durable and scratch-resistant layers can be made transparent to light, symbols can also be incorporated into backlit keys.

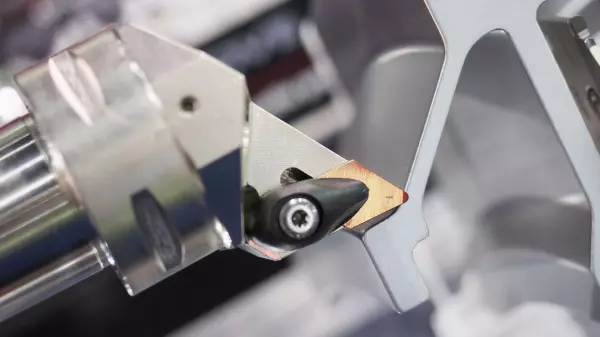

Coated mold for the kidney ensures high process reliability

Oerlikon Balzers also coats the mold for the new front kidney of the BMW iX, which is manufactured by Summerer Technologies. Due to its extreme hardness, the BALINIT FUTURA NANO coating offers very high scratch and wear resistance. The brilliant surface quality is retained thanks to improved mold filling and easy demoulding. This reduces maintenance costs and, despite the high thermal load, the mold can be cleaned with significantly more abrasion without attacking the surface. As a result, the entire production process gains high productivity, cost-effectiveness and manufacturing reliability.

For the innovative concept of the kidney for the BMW iX, the BMW Group received the Grand Award at the 20th "SPE Automotive Award" in the production area plastic exterior.

Further information on ePD technology can be found at: https://www.oerlikon.com/balzers/epd/

To the original article