Higher quality finishing / finishing processes...

Higher quality finishing / finishing processes of surgical instruments / implants Refining or ref...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Higher quality finishing / finishing processes...

Higher quality finishing / finishing processes of surgical instruments / implants Refining or ref...

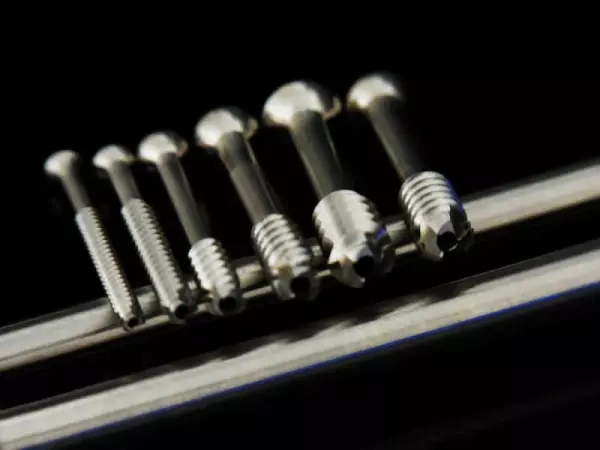

Turned parts for medical technology and mechanical...

Swiss turning Turned parts for medical technology and mechanical engineering Long turning with 2 to...

Thanks to the technical equipment and the modern machine park at Brecht, you are optimally prepared...

We are service providers in the areas of turning, milling, water jet cutting and the additive manufa...

Do you have a product in mind? We can make it! Starting with the development / construction, we are...

Test pens in quality 0,5µ, 1µ and 2µ

We offer our test pins for checking holes in two different versions. The test pins made of har...

Milling technology / milled parts - contract...

Milling technology / milled parts - contract manufacturing for medical products Milling refers to...

Saws / laser welding machine / other

1 x hydropneumatic aluminum circular saw machine Eisele Cutting area 100x100 mm or 160x80 mm, repea...

Production for countertops and interior fittings

Today, in addition to natural stone, we also process glass ceramics ( Dekton ), ceramics and quartz...

Contract manufacturing of precise turned...

Contract manufacturing of precise turned and milled parts for medical technology perame...

Décolletage & CNC turning / parts - contract...

Décolletage & turning - contract manufacturing for medical products In classic turning...

Rounding of workpieces and Rounding of cutting...

With edge rounding, we distinguish between the following: Rounding of cutting edges The object...

Turned parts, micro-turned parts, milled...

Drehen, Fräsen, Schleifen HIPP medical processes materials to turned parts and milled part i...

We manufacture milled parts from stainless steel, brass, titanium and aluminum according to a sample...

Automatic measurement on the CNC machine

Measuring on the CNC machine for more productivity hyperMILL® PROBING is the optimal and user...

CAD construction / development of medical...

CAD construction / development of medical products CAD has supplanted the drawing board and many...

Drilling of medical components, drilling of materials, drilling of products, drilling of medical devices, drilling of implants, drilling of surgical instruments, milling of medical components, milling of materials, milling of products, milling of medical devices, milling of implants, milling of surgical Instruments, turning of medical components, turning of materials, turning of products, turning of medical devices, turning of implants, turning of surgical instruments,

Drilling, milling, and turning are three common metalworking processes. In both cases, a rotating cutting tool rotates along the part's axis to create the required hole diameter. The machining process finishes the hole's diameter by removing material. The differences between turning and milling are many. For example, drilling uses up-and-down motions to create holes, while milling machines use sideways motions to create holes.

Boring, on the other hand, is used to reduce tolerances in large runs of machined or cast products. While it is extremely accurate, it is not ideal for large amounts of material removal. In order to reduce the number of cuts that must be made, drilling is typically used before boring. However, drills can refine a hole after boring. This allows the job to be completed faster. In addition, drills are portable and don't have to be set up in complicated shops.

Milling and drilling machines are similar but use different tools. While drilling drill bits are installed in a lathe for turning, milling cutters are chucked into a drill press. These machines can perform the functions of multiple individual machines, all in one machine. A machining center is a combination of a lathe and milling machine that performs all three processes. There are several advantages to each of them.

The main difference between these two processes is that turning uses a lathe, which allows for greater precision. For this reason, drilling can also produce a non-standard screw thread. By turning a screw on a lathe, a thread is produced that will not be visible once the hole is turned. This process is also known as tapping. The tap is performed either externally or internally and is commonly performed on a round part.

Face-milling: This technique removes material from the workpiece. The cutting tool is placed at right angles to the workpiece. The face-milling cutter is an example. It is the last step in the process, while the longitudinal feed is the first step. When it comes to face-milling, it is often the first and last step. This process is known as facing off, and it is used to remove the completed component from its parent stock.

Turning is a process where a rotating cutting tool presses against the workpiece and removes material. Milling, on the other hand, is a more expensive process. The rotary machining process uses a stationary workpiece. The rotary process rotates the workpiece, while milling uses a stationary part. During the milling process, the tool presses against the piece. It is often the best option for cylindrical parts with a lot of features.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.