Contract manufacturing of precise turned...

Contract manufacturing of precise turned and milled parts for medical technology perame...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Contract manufacturing of precise turned...

Contract manufacturing of precise turned and milled parts for medical technology perame...

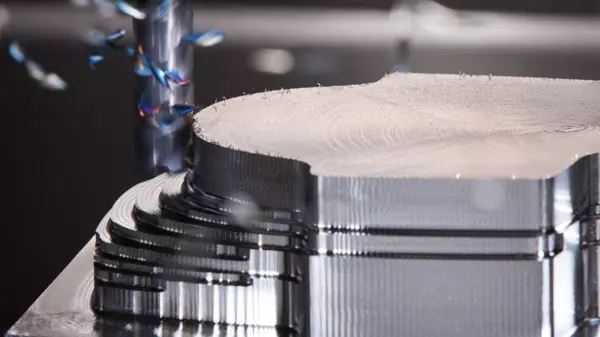

iMachining - The revolution in CNC machining Hold the knowledge and experience of hundreds of CAM...

JakuTec is your perfect partner when the customer-specific quantities are small but have to corres...

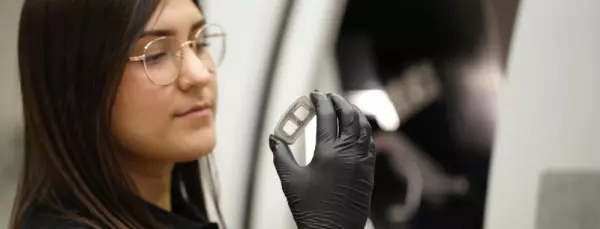

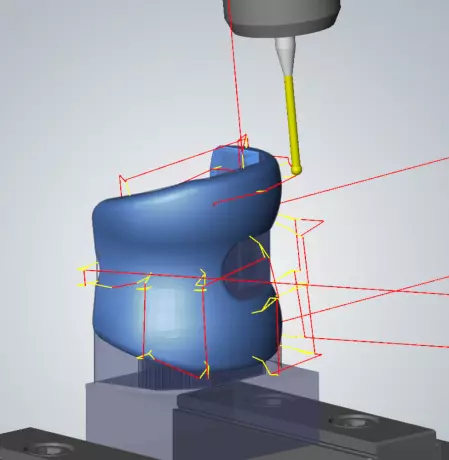

Automatic measurement on the CNC machine

Measuring on the CNC machine for more productivity hyperMILL® PROBING is the optimal and user...

CAD construction / development of medical...

CAD construction / development of medical products CAD has supplanted the drawing board and many...

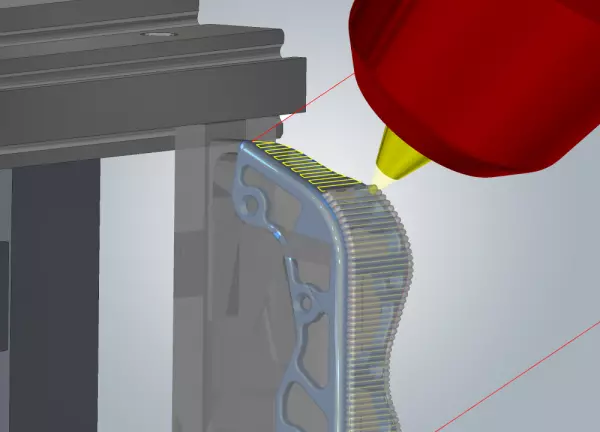

Milling Mikron MILL P 500 / MILL S 400 U

High Efficiency, High Performance, High Speed Cutting 3 milling technologies - one supplier. P...

Intelligent component alignment for medical...

Intelligent component alignment at the push of a button Do you know the problem? You align the r...

Higher quality finishing / finishing processes...

Higher quality finishing / finishing processes of surgical instruments / implants Refining or ref...

Thanks to the technical equipment and the modern machine park at Brecht, you are optimally prepared...

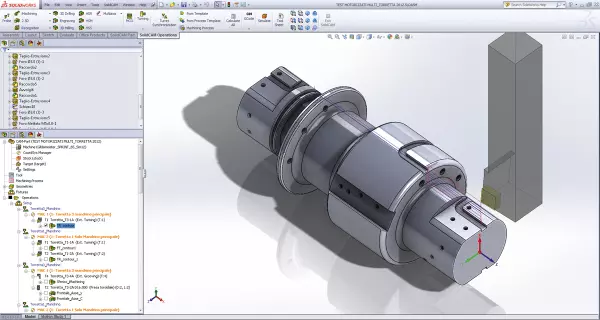

SolidCAM - The leading integrated CAM complete solution with the incredible iMachining technology...

We manufacture milled parts from stainless steel, brass, titanium and aluminum according to a sample...

Additive manufacturing for medical technology

Additive manufacturing - only really perfect with CAD / CAM Additive manufacturing offers many ne...

Production for countertops and interior fittings

Today, in addition to natural stone, we also process glass ceramics ( Dekton ), ceramics and quartz...

Tool technology for medical technology

TOOL MAKING and DEVICE CONSTRUCTION to support your production with MICHELFELDER In sectors such...

Digital Transformation / Industry 4.0

GF offers a vast choice of digital support for the customer. With rConnect and its numerous function...

Milling technology / milled parts - contract...

Milling technology / milled parts - contract manufacturing for medical products Milling refers to...

CNC machines are machines that read and follow computer-programmed commands to move the workpiece and cutting tool on multiple axes. They allow industries to create highly accurate parts quickly and efficiently. Not all parts are the same. Depending on their geometry and sizes, CNC machines can produce a variety of components, including precision medical instruments, consumer electronics, and more. Here are five of the benefits of CNC machining. Here's what you need to know before you invest in CNC machining.

The medical industry has seen significant advancements thanks to CNC machining. This type of technology allows for higher accuracy and precision and is especially suited for parts that must be sterile and have intricate geometry. It also facilitates high levels of surface finishing and cleanliness, which is essential for a successful medical operation. In addition to its medical applications, CNC machining allows for more diverse designs, allowing medical professionals to create parts tailored to each patient.

The medical industry is another example of a market that can benefit from CNC machining. Many medical devices are small, enabling them to be implanted in patients. The size of the parts must be accurate to avoid infection and help the patient heal faster. With 5-axis machining, even complex geometries and parts can be carved precisely without any manufacturing limitations. For example, medical implants can be made more accurately using a CNC machine than with a traditional machine.

CNC machining is particularly useful for medical devices, which usually require small quantities. Injection molding is uneconomical for small-scale medical devices, since the molds produced must be discarded. In addition, the cost of mold production can be very high. But with CNC machining, the cost of mold production does not have to rise. Additionally, the resulting implant will be biocompatible and compatible with a variety of materials. As such, it is an extremely cost-effective way to manufacture a medical device.

Medical devices have thousands of different parts. Most of these parts can be machined using a CNC machine. From tiny components to larger items like monitor housings, the precision required is important. Furthermore, the parts do not need to be biocompatible. Moreover, CNC machines are often wheeled around the hospital, making them portable. This makes them more robust and durable. If you're considering CNC machining, consider these three benefits. If you're in the market for a CNC machine, you can be sure that the machine you're considering is perfect for the job.

CNC machines are also used in medical equipment. Whether it's plastics or metals, CNC machining can produce various components for medical applications. It's possible to create surgical instruments, including X-ray machines, MRI devices, and other tools. In fact, many of these pieces are vital for a patient's health. If you're not sure which type of CNC machine to use, you can always consult your physician about the right machine for your needs.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.