Contract Packaging and Sterilization for...

Contract Packaging and Sterilization of Medical Products From raw material to ready-to-...

Portal and digital medical technology fair of the largest MedTech cluster in Germany

Contract Packaging and Sterilization for...

Contract Packaging and Sterilization of Medical Products From raw material to ready-to-...

Milling technology / milled parts - contract...

Milling technology / milled parts - contract manufacturing for medical products Milling refers to...

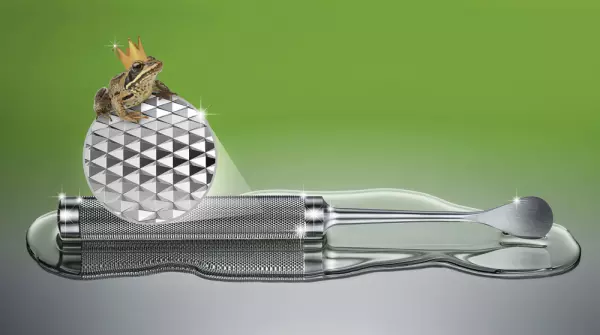

Orthopedic Products - Inserting Tools

The product range of cutting tools in the field of orthopedics includes: Phillips blades...

Healthcare & Medical assemblies

We are the reliable partner covering all areas from conception to (sterile) packaging of the finishe...

40 years of experience in electroplating For four decades, Rudolf Storz has been intensively invo...

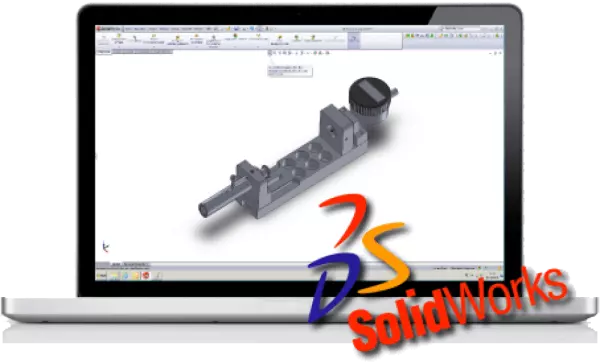

Thanks to CAD-supported development and production preparation, we have a solid basis for the manufa...

From the beginning in every JakuTec bespoke project, we work in close consultation and define prec...

Electroplating and P VD services

There are many good reasons to choose PVD technology: in addition to the low chemical loa...

CAD construction / development of medical...

CAD construction / development of medical products CAD has supplanted the drawing board and many...

Of course, there are special requirements for implant production, especially when it comes to larg...

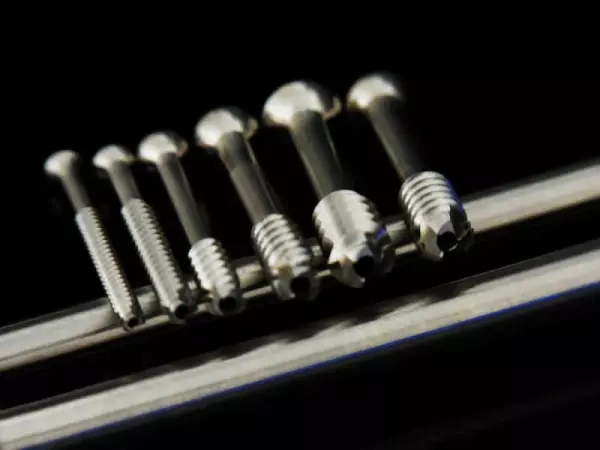

Contract manufacturing of precise turned...

Contract manufacturing of precise turned and milled parts for medical technology perame...

Our speciality: custom-made products You have a new idea or need an instrument solution for speci...

Higher quality finishing / finishing processes...

Higher quality finishing / finishing processes of surgical instruments / implants Refining or ref...

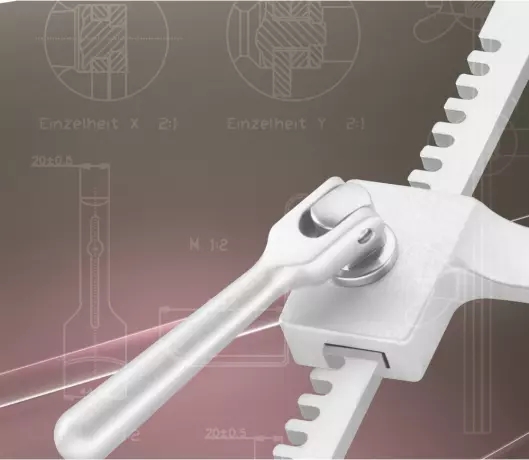

Orthopedic products - Navigating tools

Customized tools for navigating the drill holes and saw cuts

Décolletage & CNC turning / parts - contract...

Décolletage & turning - contract manufacturing for medical products In classic turning...

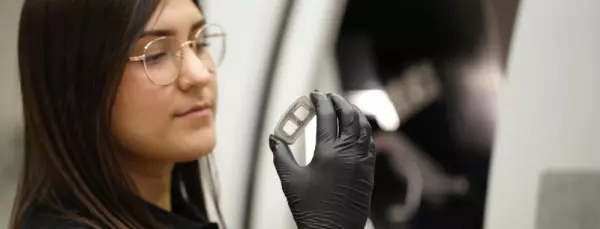

Assembly and final inspection of medical...

Assembly and final inspection of medical products Eurofins Inpac Medizintechnik GmbH assemb...

Traumatology - instruments & implants

We develop and manufacture a comprehensive portfolio for both internal and external fixation in the...

Orthopedic Products - Cutting Tools

The product range of cutting tools in the field of orthopedics includes: Bone drill Cu...

Surface finishing the perfect finish for...

Surface finishing - the perfect finish for your products Manufacturing sophisticated products is...

JakuTec is your perfect partner when the customer-specific quantities are small but have to corres...

Product development, prototyping or the manufacture of technical series are different from the pro...

Production and design of packaging for medical...

PACKAGING DESIGN Blister design Along with standard blisters for product packaging and transpo...

Metal technology / metal products for medical...

PRECISE and flexible technology solutions in metal technology and sheet metal processing We manuf...

Development of optimal packaging for medical...

Development of optimal packaging for medical products ENGINEERING In the contex...

Hiring a contract manufacturer is one of the best ways to cut costs and simplify your supply chain. The benefits of contract manufacturing are many, including reduced costs and increased efficiency. By outsourcing your manufacturing needs, you can focus on your business's core strengths, like sales, marketing, and customer service. Consider hiring Foxconn, a Taiwan-based contract manufacturer that specializes in electronics and has worked with some of the world's largest companies.

Medical device companies tend to specialize in different processes and services, so they can specialize in a specific area of expertise. Some medical device contract manufacturing firms focus on joining and converting devices, while others specialize in molding and assembly. Regardless of your business's needs, a contract manufacturer can help. They can also help your business with foreign market entry, helping you to expand your market. In addition to reducing costs and time, contract manufacturing is a great way to protect your business interests and remain competitive.

For medical device companies, turnaround time is an important consideration. Good contract manufacturers must be able to deliver on time, whether a medical device is an IV drip or a complex surgical implant. A good contract manufacturer will be able to provide references and case studies for their work. If you're unsure, ask if they're financially stable. The right contract manufacturing company will quote a fair price up front. They'll also provide references or case studies.

Medical device contract manufacturers are experts in certain tasks and processes. They can offer valuable knowledge gained from frequent practice. They can also provide assistance for the inventors, clients, and customers of medical devices. They can also manage the supply and delivery of their products, thereby minimizing risk. And with a partner that can provide you with the expertise you need, you'll be able to focus on your product development. You'll be glad you chose the right contract manufacturer.

Medical device contract manufacturers must meet strict technical specifications and maintain a schedule. For this reason, quality contract manufacturers should have proven themselves in the medical device industry and have the right equipment. These companies can also produce medical devices much faster than in-house manufacturers. They can also reduce their overhead costs by partnering with a contract manufacturer that specializes in their field. These medical devices are highly sensitive, which requires a high level of expertise in the industry.

A good contract manufacturer should be flexible. It can accommodate the needs of a business, which can lead to improved profits. A good contract manufacturer can reduce your costs while increasing your productivity. In addition, it will also give you a global footprint. Moreover, you can easily customize the contract to your specifications. If you're a pharmaceutical firm, a high-quality contract manufacturer can be a crucial element to a successful business.

Become a digital exhibitor yourself in the online portal of the largest and best-known MedTech cluster region in Germany and inform the world of medical technology about your products and services as well as about news, events and career opportunities.

With an attractive online profile, we will help you to present yourself professionally on our portal as well as on Google and on social media.